Introduction of wastewater treatment by MBBR method

- Moving Bed Biofilm Reactor

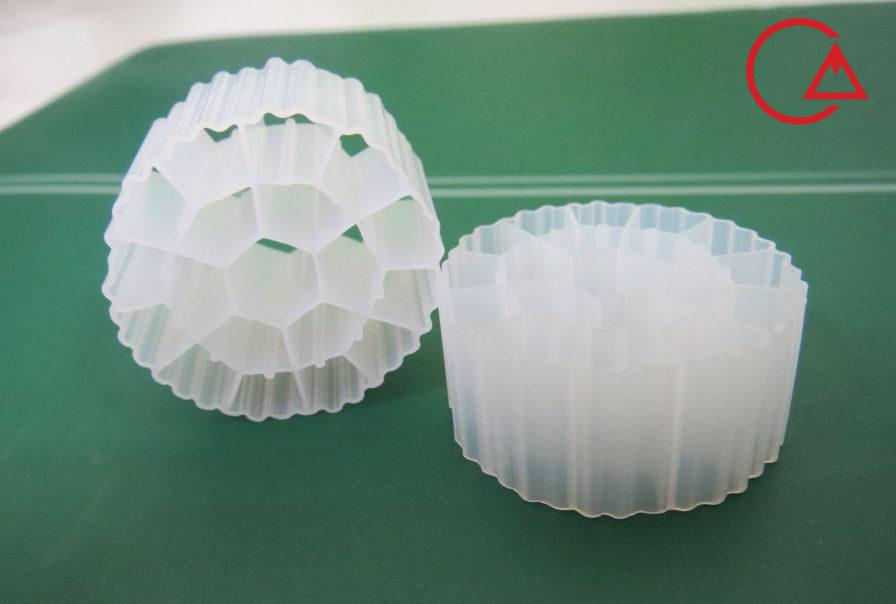

- Adherent growth with mobile media

- Small plastic parts cause the growth of attached bacteria.

Steps of wastewater treatment package by MBBR method

- Garbage to preserve MBBR media

- Balancing tank

- MBBR tank

- Sedimentation tank

- Chlorination tank

- Sludge digestion tank

Components of growth unit attached with MBBR mobile media

- CS structure with epoxy coating

- Small size garbage collector at the entrance

- Sludge pump

- Blower roots or side channel according to the size

- Fine Bubble Diffuser

- Chlorination package

- Media packing

- Automatic switchboard with emergency switch

Where is attached growth with moving media used?

- Wastewater treatment of hotels, restaurants and towns

- Wastewater of entertainment and sports centers

- Industrial wastewater treatment

Advantages of MBBR method in sanitary wastewater treatment

- Better removal of cyanide, formaldehyde and phenol

- High dilution ability and reduction of sedimentation pond load

- Increasing the settling power of the resulting materials

- Increasing the speed of the aeration process and, as a result, lower energy costs

- No need to return the activated sludge from the secondary clarifier to the aeration pond and the sufficiency of the stuck sludge

- Optimal use of small space

- Nitrification power

- No need for repairs and overhaul

The disadvantages of this process include the following:

- The need for more aeration and therefore a stronger blower

- Higher energy consumption than other methods

MBBR process design parameters to remove BOD and nutrients

| parameter | the unit | Range of values |

| Anoxic time | h | 1-1/2 |

| Aerobic dwell time | h | 3/5-4/5 |

| biofilm surface | m²/m³ | 200-250 |

| BOD loading | Kg BOD/m³.d | 1-1/4 |

| Amount of hydraulic load of the secondary clarifier | m/h | 0/5-0/8 |

MBBR/SC process design parameters

| parameter | the unit | Range of values |

| MBBR | ||

| Biofilm surface area | m²/m³ | 300-350 |

| organic loading rate | kg BOD/m³.d | 4-7 |

| MLSS concentration | mg/l | 2500-4500 |

| SC | ||

| SRT | d | 302 |

| MLSS concentration | mg/l | 1500-2500 |

| SVI | ml/g | 90-120 |

| Hydraulic dwell time | h | 0/6-0/8 |

| Re-aeration tank | h | 0/6-0/8 |

| MLSS | mg/l | 600-8500 |