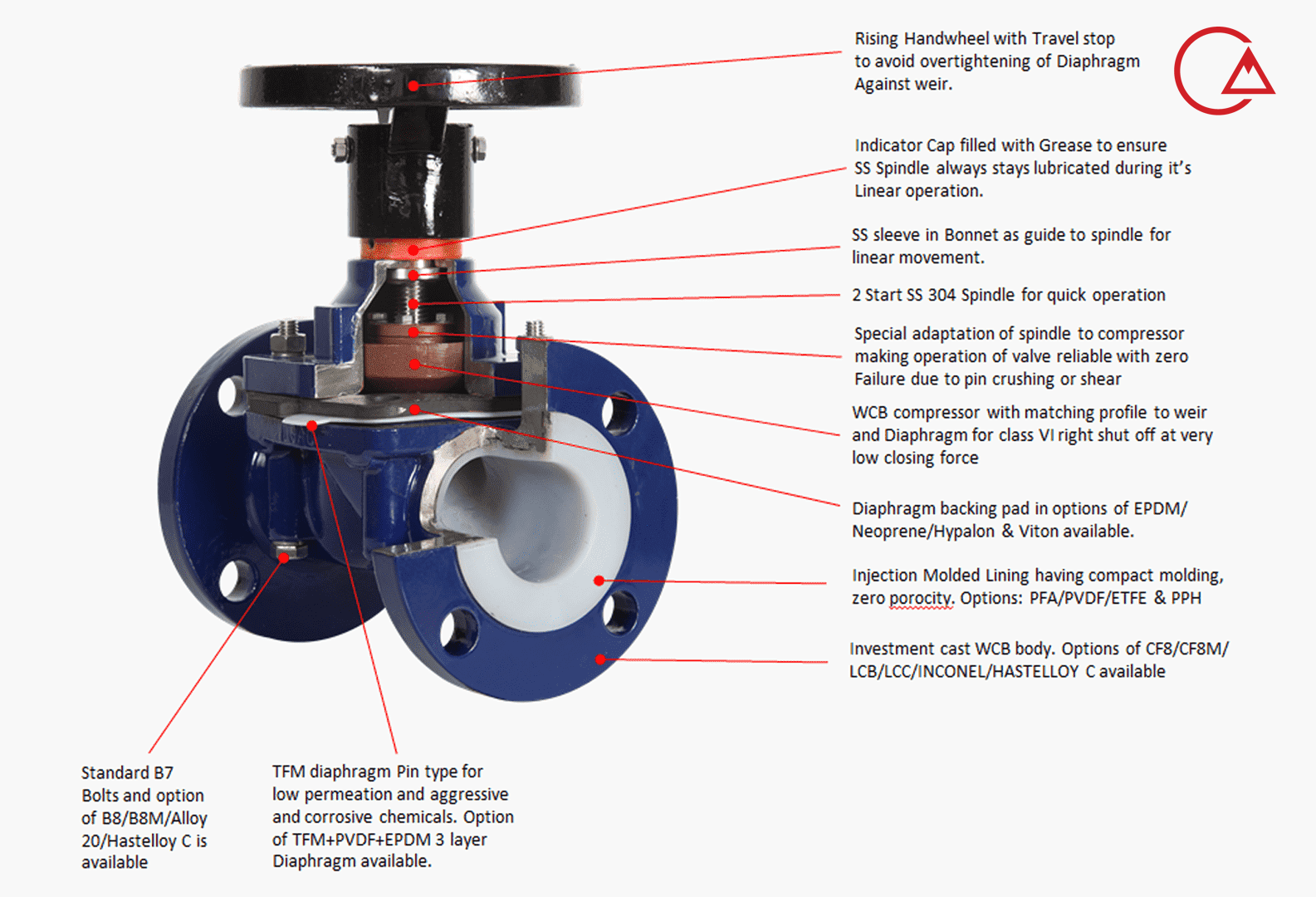

Diaphragm valve is a linear valve that is used to open, close or control fluid flow. The reason for naming the diaphragm valve is due to the presence of a flexible disc that is in contact with the seat on the top of the valve body and forms a seal.

A diaphragm is a flexible, pressure-sensitive part that transmits force to open, close, or control a valve. Diaphragm valves are similar to needle valves, but instead of using an elastomeric bushing in the valve body, they use an elastomeric diaphragm (Elastomeric Liner) to separate the fluid flow from the blocking part.

Diaphragm valve control method

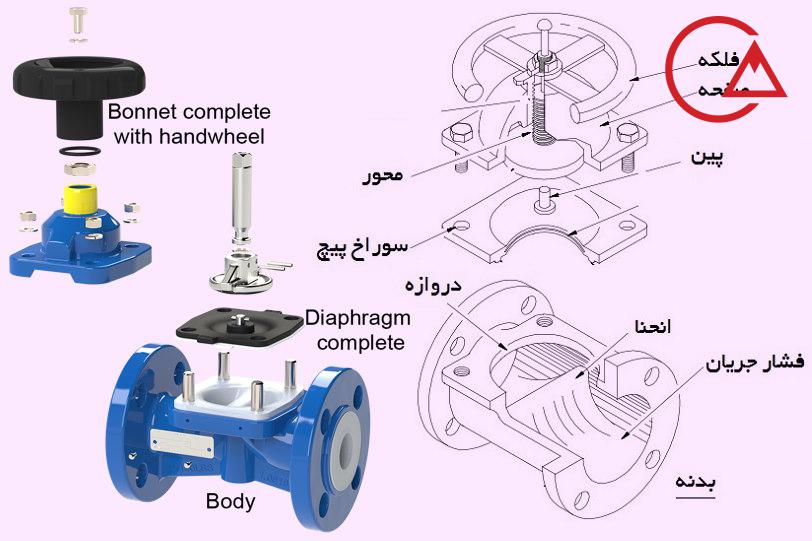

Diaphragm valves use a flexible diaphragm attached to the compressor by an integral rod. Instead of tightening the bushing to block the flow of fluid, the diaphragm is placed in contact with the bottom of the valve body, thus cutting off the flow of fluid.

Manual diaphragm valves are an ideal choice for fluid flow control because they create a variable and precise passage to control the pressure drop within the valve. The handle of the valve is rotated to adjust the desired amount of fluid passing through the valve. To open and close, the valve handle is rotated to push the compressor diaphragm toward the bottom of the valve body and block the flow of fluid, or move up from the bottom of the valve and force fluid through the valve.

Diaphragm valve operation

The diaphragm is connected to the compressor by means of a rod that is integrally molded into it. The compressor is pushed up by the valve handle to maintain or increase the fluid flow. To stop or reduce fluid flow, the compressor is pushed down and the diaphragm is pressed against the bottom of the valve body.

Diaphragm valves are excellent for controlling the flow of fluids containing suspended solids and can be installed in any position. Weir-type diaphragm valves have a better performance than Straight Through Type Diaphragm Valves for fluid flow control because the design of the large blocking part along the seat allows the valve to open quickly. The diaphragm acts as a seal and prevents fluid leakage between the valve body and the outer cover.

Diaphragm valve operation

Types of diaphragm valves

Diaphragm valves are considered among industrial valves and are available in two main types:

Weir-Type Diaphragm Valves and Straight Through Type Diaphragm Valves

Both types of valves have the same basic structure but have different body and diaphragm.

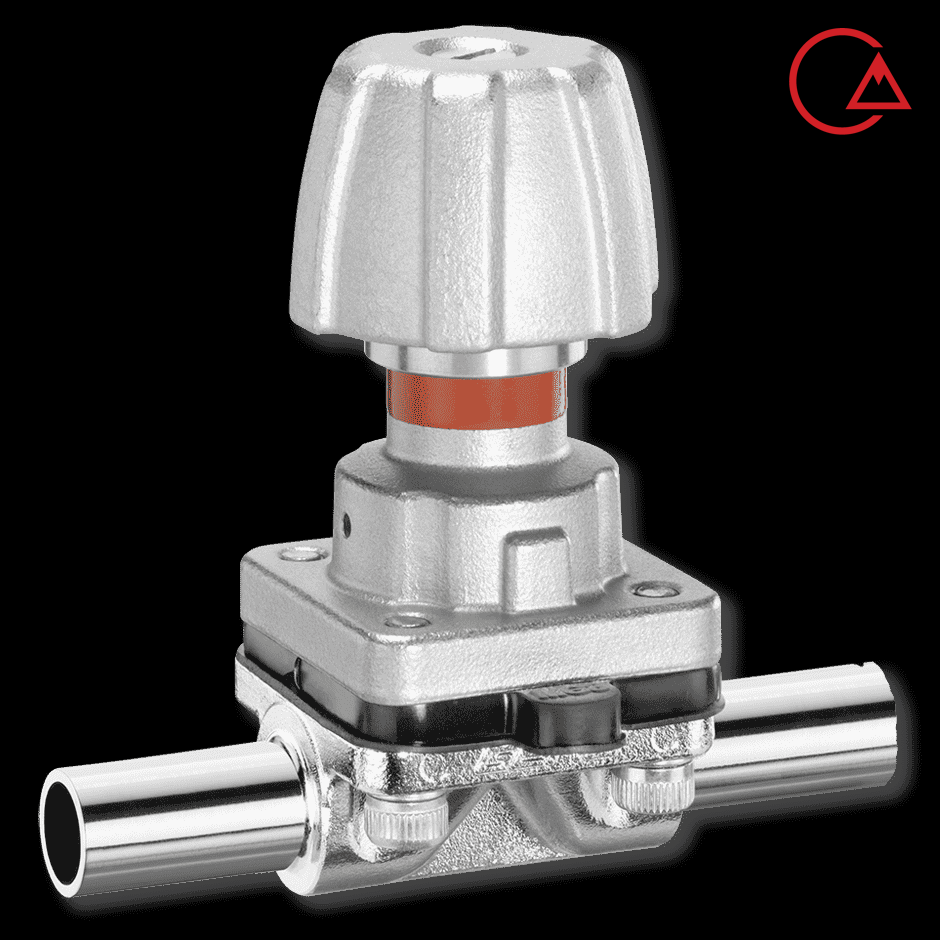

The saddle-shaped design is the most popular type of diaphragm valve and is very suitable for general applications or corrosive and abrasive services. Their best use is in controlling small currents. The body of the saddle diaphragm valves has a raised edge that is placed in contact with the diaphragm. Saddle valves have a smaller diaphragm because there is no need to stretch the part as much.

The part can be heavier and therefore the valve can be used for high pressure and vacuum services. The saddle design consists of a two-piece compressor. To create a relatively small passage in the center of the valve, the first rotation of the valve stem raises an internal compressor, and instead of the entire diaphragm lifting the saddle when the valve opens, only the central part of the diaphragm is lifted. When the internal compressor is opened, the external compressor also rises in line with the internal compressor, and the additional flow control is similar to the control function in other valves. The article What is a ball valve can also be useful.

Saddle type bodies have covers that are recommended for hazardous liquids or gases because hazardous materials will not leak into adjacent systems if the diaphragm fails. These valves are also recommended for food processing industries because they have a self-draining body.

Weir-Type Diaphragm Valves

The direct type can be used in situations where the flow direction changes within the system. The bottom of the body of these valves is smooth and parallel to the fluid flow. This design allows the fluid to pass through the valve without obstruction. The diaphragm must be made of a flexible material so that this mechanism can reach the bottom of the valve body; This issue can shorten the life of the diaphragm. The use of these valves is excellent for mud, slurry and other viscous fluids, but they are not suitable for high temperature fluids.

Straight Through Type Diaphragm Valves

Both types of valves create a simple and efficient path for fluid flow so that minimal pressure drop occurs in the valve.

Connection type

Diaphragm valves are connected to a variety of piping systems. Their connection type should be selected based on the existing system requirements and the appropriate type of sealing. Several connection types are available:

- Threaded : The threaded ends of diaphragm valves have internal and external threads so that the pipe can be screwed into or onto the valve . This is a simple and popular design for many piping systems.

- Compression fittings : Compression fittings seal pipe joints without using solder or threads. At the same time as one of the nuts is tightened, the seal is formed and the gasket is compressed around the second pipe and a sealed connection is created.

- Bolt flange : Bolt flanges are connections that can be used at the inlet or outlet of the valve.

- Clamp flange : Clamp flanges are spring hinged flanges that wrap around the pipe to form a connection.

- Tube fitting : By using tube fittings, it is possible to directly connect the pipe to the valve.

- Butt weld : A butt weld holds a butt joint (i.e., a joint between two plates, rods, or sections). The two pieces are placed side by side but do not overlap and do not interlock.

- Socket weld /Solder : Socket weld joints between two parts are soldered to each other so that it becomes very difficult to separate them.

- Metal face seal : Metal face seals use a metal washer that is sandwiched between two connected parts. The gasket creates a face seal on both sides of the connection.