- Menu pump in decades ۱۹۳۰ by Renee mono invention was more for pumping the fluid thickens used

- This type of pump relative to the transfer pump, other (like دوزینگ pump) strength more enjoys, and thus has more power can also be

- Mono pump in category pumps positive displacement (to be fixed and uniform fluid from the inside of the compartment to the outside can see) placed

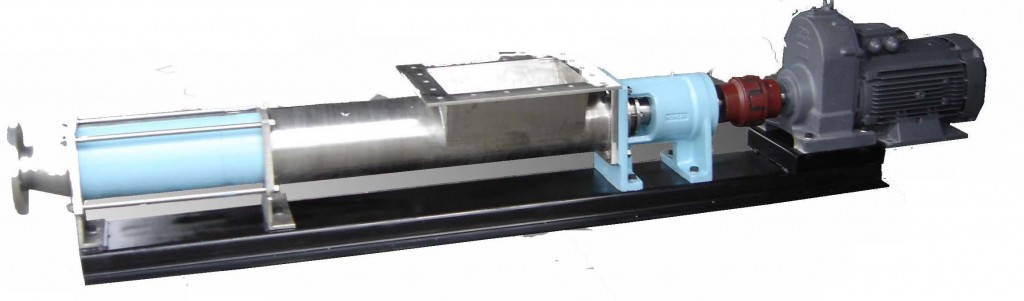

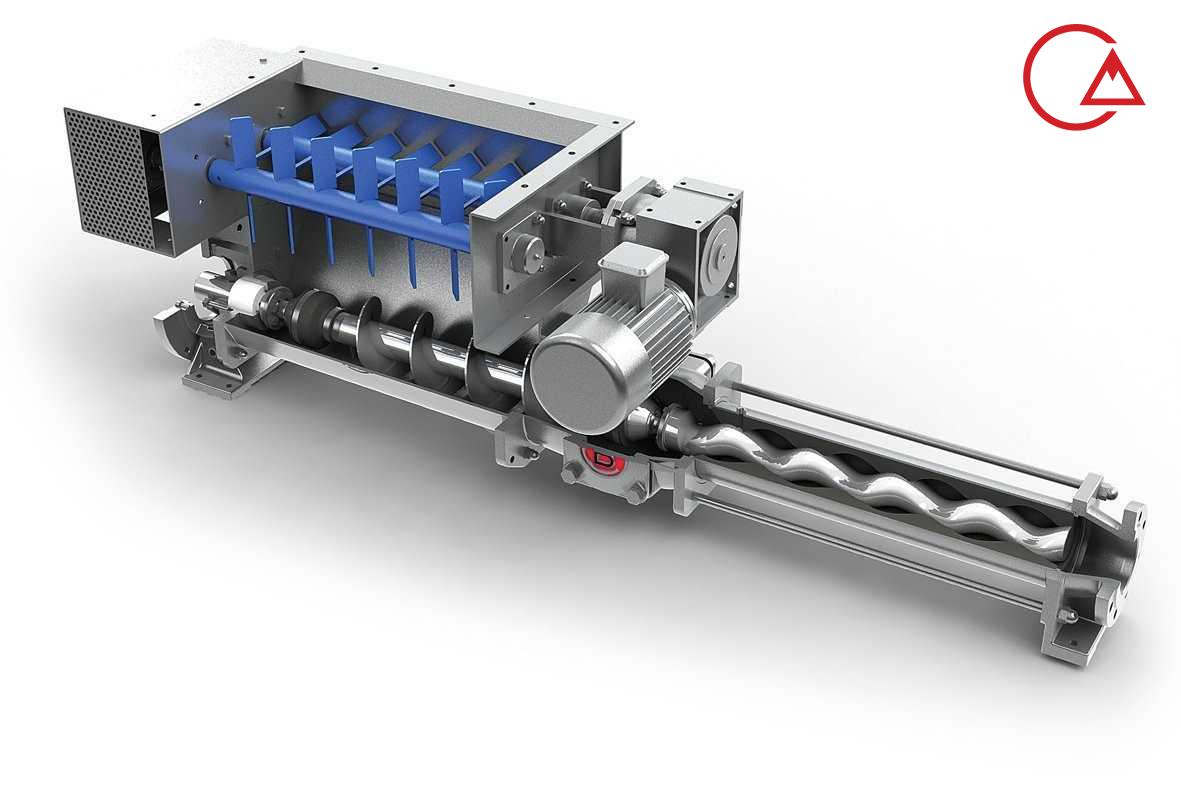

- Consists of two parts, the rotor and the stator is that the step rotor half step, the stator is

- Rotor with moving out from the center stator fluid to the front and finally the action of pumping will do

- In industry, the gimmicks a lot of this type of pump are like : mono pump – thick cache – single screw – spiral – pump spiral out from the center – the pump cavity, progressive and …

The components of the mono pump

- Rotor spiral single way

- The stator with the cavity of the spiral, two-way

- Electric motor

- Geared variable speed

- Metal chassis

- Electrical

Building mono pump

- Usually, the rotor of stainless steel, smooth and polished, and is a member of stimulus pumped into account it comes

- The stator compartment that mimics the rotor of … sex and its depending on the type of fluid, plastic (وایتون that the best thermal resistance in all elastomers are)natural rubber NR-EPDM and nitrile NBR is selected

- Gearbox and electric motor with respect to the viscosity of the fluid, and-the type of fluid-pressure required-the amount of the Dubai specified is

- Body مونوپمپ usually stainless steel or cast iron is selected

- Sealing system due to corrosion and chemical – temperature – type of fluid and … the choice is

Producers mono pump in the world

- Germany ProMinent

- Nash, Germany, Netzch

- Franklin Electric Franklin Electric

- Oil Well national وارکو National Oilwell Varco NOV

- Flowrox

- Seepex

- Zune’ve PCM

- Jessberger

A sample of the fluid that means of this type of pump transmitted

- Chocolate

- Molasses

- Milk of lime

- Glue

- Dishwashing liquid

- Resin

- Cream

- Honey

- Tomato paste

- Toothpaste

- Gelatin

- Cement mortar

- Polymer

The naming of these pumps

- These pumps to submersible pumps, screw also the reputation they have

- And specifically for transferring material with high viscosity and variable, especially to add soluble polymer to water filtration systems are designed.

- The pumps from the category pumps Progressive Cavity Pump are

- That pumps Screw is also the reputation they have.

- These pumps are submersible pumps transfer has been, and specifically for transferring material with high viscosity (up to 5000 mPas) and the viscosity variable, especially to add the solutions of the polymer to water filtration systems are designed.

- Sex, rotor and body, the pumps, SS, sex and the stator, they FPM (وایتون) has been

- And in different capacities provided below.

The benefits of mono pump to pump other

- A pump positive displacement is

- Low noise

- Dubai smoothly and no need to یکنواختکننده

- Application for various materials

- Pumping the material with ویسیکوزیته high

- Pumping the material with the solid particles and the particles sticky

- Uniform being stream

- Low maintenance cost

- Easy repair

- Health for the food industry

- Pumping the sensitive materials without damage to the tissues of the substance like blood

- Pumping the material with غلطت high

- Low اصحلاک

Parts of mono pumps that require inspection are

- The rotor or ماردون (تکراهه or cable connector) (ROTOR)

- The stator (a hole in the cable connector, and three-way) (. pushbot. t)

- گاردان and parts, power transmission (JOINT PARTS)

- بیرینگ (BEARINGS)

- Parts sealing (SEALS)

- واشرجات And اورینگ (GASKETS & O-RINGS

The application of mono pumps in the food industry

Transmission fluid edible viscose like

- Liquid chocolate

- Prepare the dough

- Cream

- Honey

- A variety of sauces and paste

Mono pump in which industries are

- Urban wastewater treatment and industrial

- Food and drinking water

- Refinery

- Pharmaceutical industry

- Color reproduction

- Handcrafted sugar cane

- Plastic Industries

- Mine

- Living, dining and fluid transfer

Mono pump fit which fluid is

- Of the fluid, and the concentration is very بـالا

- Corrosive material

- Materials the particle abrasion

- Fluid with solid particles, like lime juice

- All kinds of slime and Sludge

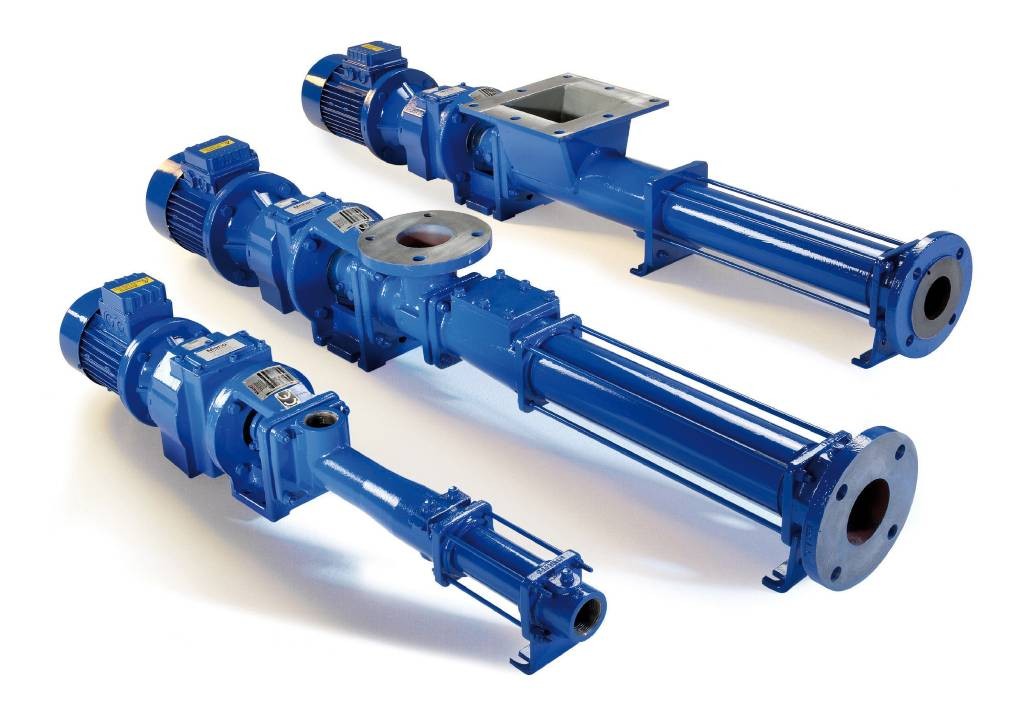

Mono pump سیپکس Germany SEEPEX

- مونوپمپ of اسکروی spiral ALLWEILER one of the top brands are quite famous and known in all industrial sectors is

- Such as injection and دوزینگ, etc., pumping, materials, viscous and pasty., the food, etc., chemical

- This مونوپمپها widely used in the industries of water and wastewater treatment also are used.

- Company ALLWEILER Germany independently established

- But now downline American company US GROUP, COLFAX, is, of course, still the location of the company Germany is

- ALLWEILER a range of pumps for all applications suggest

- In addition to pumps اسکروی spiral of the company, other types of pumps, such as centrifugal and Tripple screw ( three ماردونی) also for chemical industry, petrochemical, next to other sections of your produce.

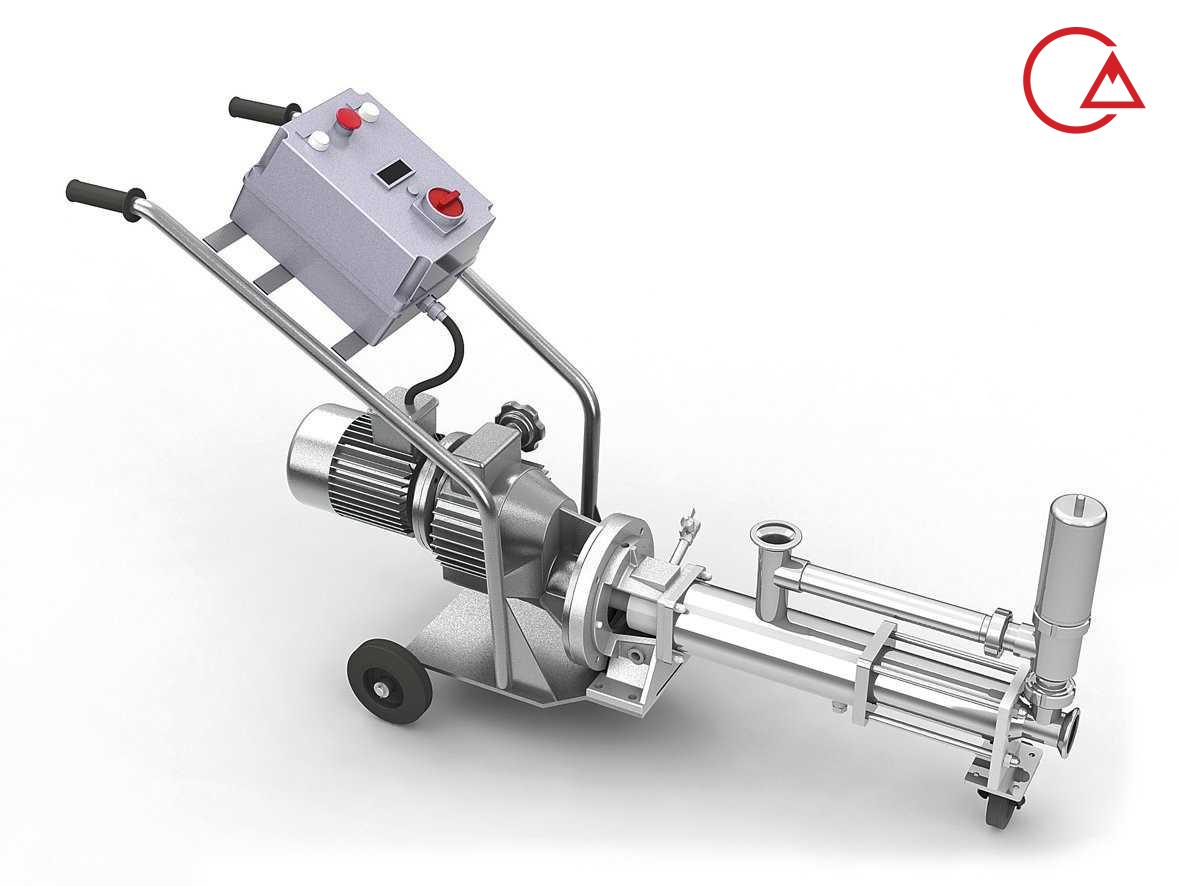

Company introduction manufacturer مونوپمپ PCM

- Pump اسکروی spiral PCM in between the beneficiaries to the high quality of the celebrities.

- The company is in the field of pump related industries are different , with an emphasis on industry, upstream oil and gas company, which provides.

- In 1930, an engineer Frenchman named René Moineau pumps اسکروی Helix invention

- In 1932, the company PCM’s established.

- In 1970, the disposal of the company’s PCM to the industry, pump دلاسکو was assigned.

The variety of models of pumps, brand, PCM

- ID

- I

- H

Mono pump, Nash, Germany NETZSCH

- The company NETZSCH one of the largest and most famous companies, mono pump

- As well as a family company in Germany, under the collection, holding Erich NETZSCH is.

- The main activity of the company on the three branches build systems, pumping, etc. systems پرسکاری and Mill and parts instrumentation industry.

- مونوپمپهای اسکروی (pump spiral/ماردونی) company NETZSCH in various industries such as food industry, water and wastewater, pharmaceutical and health applications.

A variety of models pump brand NETZSCH

- NMP

- NMD

- NML

- NE

- NEMO

مونوپمپ آلویلر America ALLWEILER

- مونوپمپ of اسکروی spiral ALLWEILER one of the top brands are quite famous and well-known

- In all industrial sectors, such as injection and دوزینگ, etc., pumping, materials, viscous and pasty., the food, etc., chemical and… is

- This مونوپمپها widely used in the industries of water and wastewater treatment also are used.

- Company ALLWEILER Germany independently established

- But now downline American company US GROUP, COLFAX, is, of course, still the location of the company Germany is

- ALLWEILER a range of pumps for all applications suggest

- In addition to pumps اسکروی spiral of the company, other types of pumps, such as centrifugal and Tripple screw ( three ماردونی) also for chemical industry, petrochemical, next to other sections of your produce.

The variety of models of pumps, brand, ALLWEILER

- SEP

- SNP

- AE

- TecFlow

مونوپمپ Borman’s BORNEMANN

- Company BORNEMANN in 1853 in Obernkirchen , Germany was established.

- The company in 2012, the ownership of the industrial group, ITT America came in.

- BORNEMANN one of the factories reputable in the field of pump storage especially pumps, triple screw (three ماردونی) is.

- Pump اسکروی spiral of the company to various industries and diverse applications, are produced.

- These pumps to a capacity of from 1 to 250 cubic meters per hour and for all, up to 24 times, or in some models even up to 80 times designed.

A variety of models pump brand Bornemann

- ES

- EU

- ER

- EL

- EH

- B

The application of mono pump in the water and wastewater industries

Refined preliminary/primary (PRIMARY TREATMENT)

- During this process, the water to the inside of the tank, settling early for the

- There, sludge and solids, heavy on the floor of the tank sedimentation and pigments, etc. Greese and solids, the existing style in the sewers on the surface of the water, floating around

- Solids, heavy sediment been on the floor of the tank for continuous slowly by Scarbber vacuum cleaner has been

- To the funnel-shaped form of the end of the Tank Guided are collected and to the side of the unit, filtration and removal of the sludge transferred crafted

- Oily substances, etc. گریسها and material floating at the top of the tank level, also by Skimmer available at the top of the tank collected

- And the water remaining enters the stage filtration secondary/ biological filtration is

Secondary filtration/purification of biological (Secondary Treatment)

- The phase of the secondary filtration once the beginning is that the material is suspended and non-could be solved with the (suspended and dissolved) from water separator شدهباشد

- This stage of filtration with the use of micro-ارگانیسمهایی that environmental conditions Controlled are done

- These micro-organisms, organic material, dissolved in water consumption drawn

- Components that are less soluble in water are clots are

- And at the bottom of the tank جمعمیشوند finally, the material from the bottom of the tank are gathered

- In some cases, before the exit of water from the stage and enter into the final stage of purification, a process of isolation to remove the micro-organisms from water, refined required.

Filtration stage III/ advanced (TERTIARY TREATMENT)

- Filtration third stage is the advanced treatment is also known as the process is

- Where the water free from substances appreciated that at the stage of secondary filtration removal have not been

- Before the treated water, chooses to side مصبهای the sea or rivers, guided

- And enter the ecosystem, be, etc. should be in terms of chemical and physical minimum standards to observe

- Therefore, at the stage of نصفیه advanced materials contained in water, such as نیروژن, etc. P, heavy metals, and solid materials impossible to solve. the amount of Virtual that the environment specified events, etc. will be reduced.

Filtration and removal of sludge and solids (SOLIDS PROCESSING)

- Solids and لجنهایی that in the process, filtration, primary and secondary water separated should be the way to safe and effective disposal of return

- The aim of the actions taken at this stage, reduce the amounts of compounds, organic, and avoid creating risks is

- That microorganisms can be to create

- At the end of this step, operation, disposal or burning of solid materials and لجنها it can be done

- And with even one of them in the process of production fertilizers chemical used