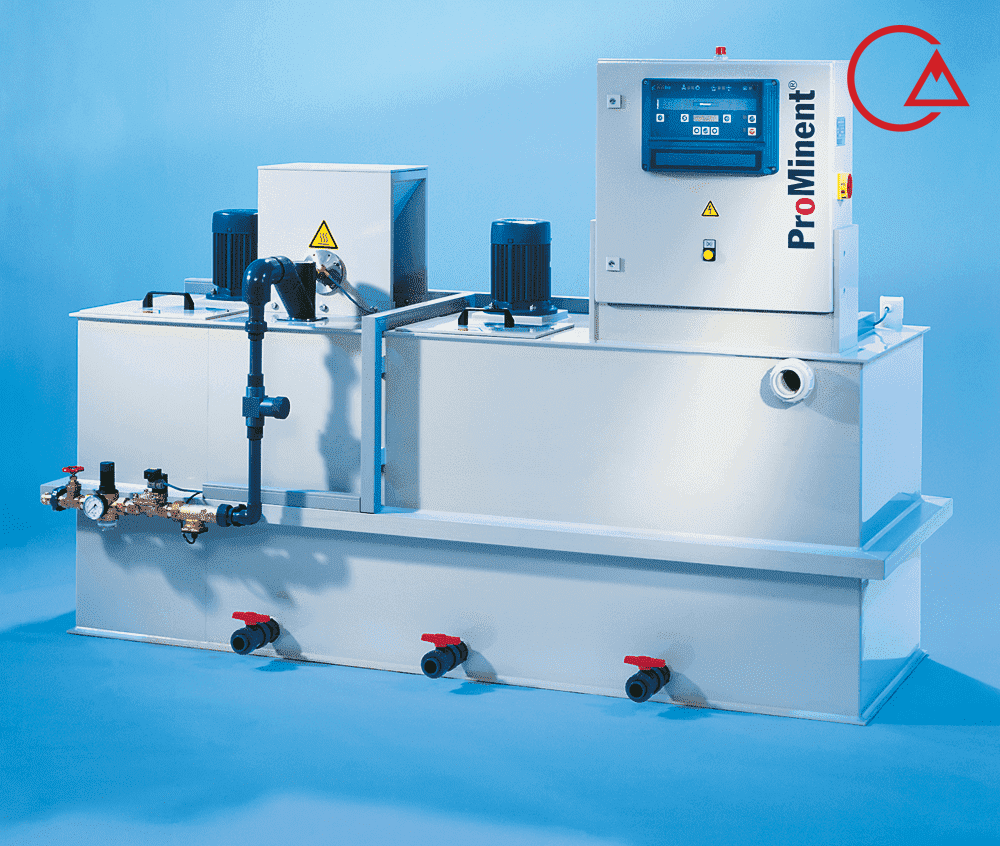

Automatic polyelectrolyte preparation and dosing unit

The automatic polyelectrolyte preparation and dosing unit consists of a rectangular tank divided into three compartments. The first compartment, for dilution, is complete with polyelectrolyte loading hopper, micro-screw batcher and relevant variable speed drive, fast stirrer for the polyelectrolyte mixing, inflow system for the dilution water and relevant solenoid valve, flow meter and pressure relief; the second compartment, for the polyelectrolyte mixture ageing, is equipped with slow stirrer and bottom suction and drain system. The third compartment, for ageing and storage, is used for the mixture storing and is provided with slow stirrer and suction and delivery system for the polyelectrolyte solution.

Every stirrer has two impellers fitted on its shaft, each one with four sloping blades. The polyelectrolyte preparation occurs automatically: in fact, once the concentration (from 0.05% to 0.5% by weight) has been established, the dosing of dilution water and polyelectrolyte starts automatically. The solution at the PDPA outlet can be further diluted in the network, if required. The preparation unit is provided with alarms activated by the failure of the dosing screw or shortage of dilution water, insufficient level of polyelectrolyte in the hopper, faulty operation of the stirrer. The standard construction is in stainless steel.

Strenghts

- COMPLETELY AUTOMATIC OPERATION.

- PRESENCE OF THREE COMPARTMENTS, ONE FOR DILUTION, ONE FOR AGEING AND ONE FOR STORAGE.

- PERFECT POLYELECTROLYTE DILUTION.

- PRESENCE OF ALARM SIGNALS FOR OPERATION IN ABSOLUTELY SAFE CONDITION.

Polyelectrolyte Preparation Units

Polyelectrolyte is used as flocculant agent when treating potable process and waste water and to accelerate or improve the solid/liquid separation process. They are added to water or wastewater sludge in the form of highly diluted solutions. The long experience of AES in the field of sludge dewatering has led to the development of preparation and dosing of organic mediums. Vast experience with many supplied plants absorbed knowledge of the application of the most different flocculation mediums led to conception of the Standard plants POLIDOZ M and POLIDOZ A.