What is a diaphragm pump?

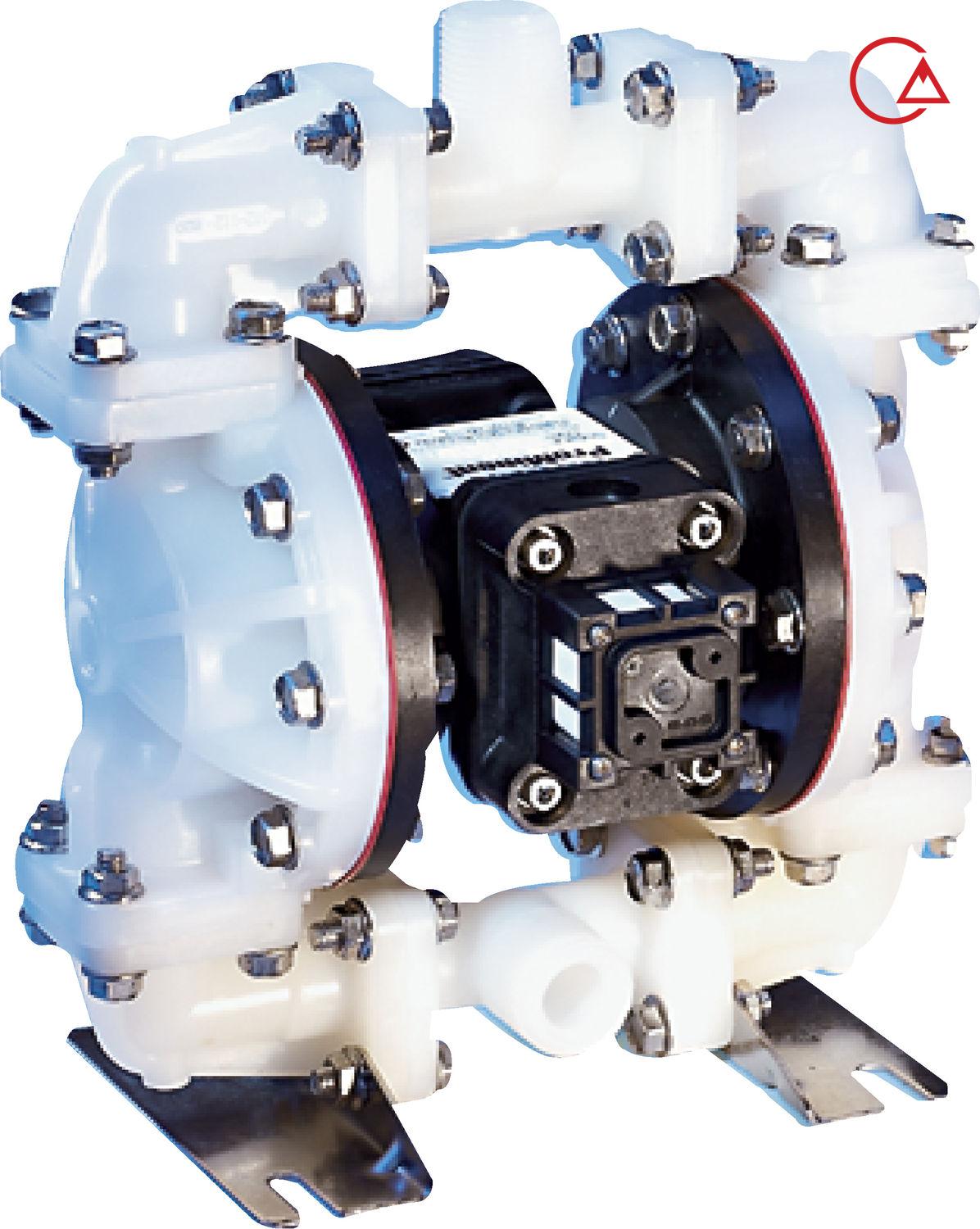

The diaphragm pump has a high suction power and also does not require ventilation. It does not have mechanical seals and is explosion-proof, and also with its very easy use, it is used for pumping all kinds of acids, bases, liquefied gas, edible and industrial oils, solvents, etc. Types of diaphragm pumps include pneumatic diaphragm pump, manual diaphragm pump and electric diaphragm pump. Among its features, we can mention its working mechanism, reasonable price, high efficiency and ease of use, which are used to pump all kinds of fluids.

Diaphragm pump

These pumps have two diaphragm plates and, depending on the type of fluid that is flammable or simple, electrical systems or pneumatic actuators are used.

Introduction video of diaphragm pump (pneumatic pump – air pump)

Technical specifications of Diaphragm Pump

How diaphragm pump works (pneumatic)

To get acquainted with how the diaphragm pump works, it is necessary to first know some points about these pumps. The most common type of these products are dual-channel diaphragm pumps. These pumps have two diaphragms and a chamber, the diaphragms of which are connected to each other by an interface rod. These diaphragms move in a linear direction. Pneumatic pumps have an air distribution valve. This valve is responsible for injecting compressed air behind the diaphragms. By changing the air behind each diaphragm and draining the air from the other diaphragm, the diaphragms move. The diaphragm pump works in such a way that by performing this reciprocating operation continuously and reducing the pressure, the fluid enters the pump tank and in the next step, with increasing pressure, the fluid is transferred out and pumped.

Diaphragm pumps use one-way valves, hoses and valves. Tongue-pump pumps can pass fine solid particles. In these pumps, due to the presence of solid particles and the tendency of these particles to settle, the pump outlet is located at the bottom of the pump chamber so that the fluid with solid particles can be easily removed. In pumps whose outlet is located at the bottom, the transfer of viscous fluid with low flow and high pressure due to the lack of air out of the chamber, the displacement of the pump is reduced unless the flow rate is high and the air is discharged with the fluid.

Diaphragm pumps with ball valves are the most suitable type of these pumps. In these pumps, the inlet is located at the bottom of the diaphragm chamber and the outlet is located at the top of the chamber. This design in diaphragm pumps allows the gases inside the pump chamber to be easily evacuated due to the lightness associated with the fluid. The outlet located at the top of the pump allows air or vapors inside the pump to escape easily due to the lightness with the fluid.

The diaphragm, which is usually made of elastomer, is used as a seal or mechanical seal, and due to its material, it can be used in a wide range of temperature and pressure without the need for lubrication.

Diaphragm pump function

Diaphragm pump feature (air pump)

In diaphragm pumps, the power consumption and the amount of air consumed by the pump is related to the flow and output of the pump. If the pump output flow is zero, the amount of air consumed is at its lowest, and when we have the maximum flow, the amount of air consumed by the pump is at its highest. This feature of diaphragm pumps helps the pump output current to be usable at all intervals.

In diaphragm pumps, the compressed air pressure, flow rate and NPSH determine the outlet pressure and the head has no effect. The amount of NPSH required in a diaphragm pump is the same as for other reciprocating pumps. The criterion for determining NPSH is the rate of efficiency drop at constant velocity or flow, which is about 3%.

Diaphragm pump actuators

Air Operated Double Diaphragm Pump, also known as AODD Pump. These products are made with different drivers. like the:

Electrical diaphragm pump

Manual diaphragm pump

Pneumatic diaphragm pump

Pneumatic compressed air starters are more widely used in this type of pumps and are often known by this name in the industry.

Electric diaphragm pump

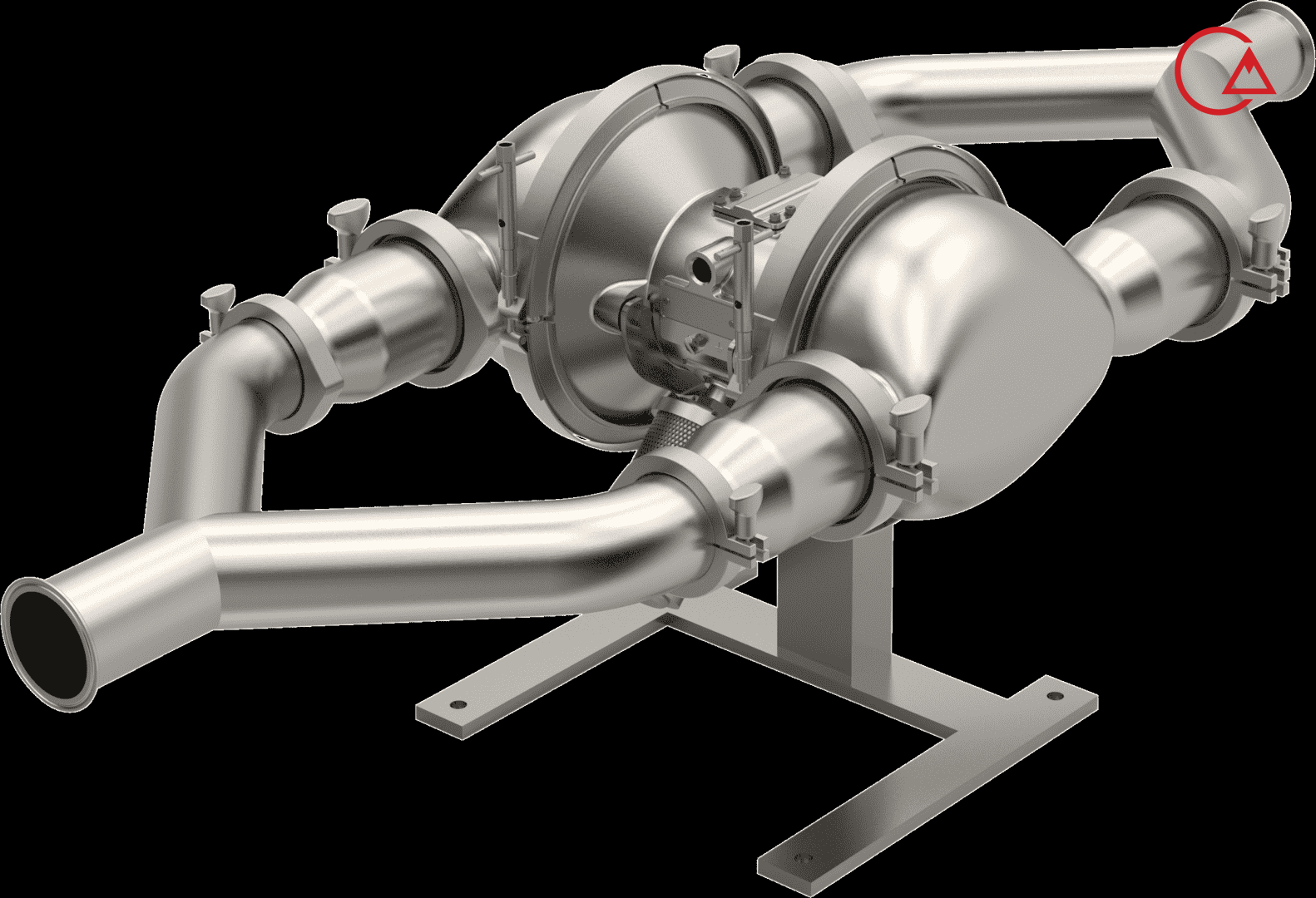

Some manufacturers of diaphragm pumps have developed diaphragm pumps with pneumatic actuators. Diaphragm pumps with electric drive can be used when compressed air is not possible. This series of diaphragm pumps usually has a lower efficiency than diaphragm air pumps. The following figure shows an example of electrically driven diaphragm pumps.

Electric diaphragm pump

High pressure diaphragm pump

As mentioned, diaphragm pumps are capable of producing 8 times the output pressure. To achieve higher pressures, some diaphragm pump manufacturers have developed high-pressure diaphragm pumps. Diaphragm pumps are often one-to-one and produce 1 outlet pressure per 1 inlet air pressure. High pressure diaphragm pumps have 2 outlet pressures for 1 inlet pressure. This series of diaphragm pumps are mainly used in filter press systems. High pressure diaphragm pumps are often marketed in metallic materials.

Balach pressure diaphragm pump

Working range

Size: 3/8, 1/2, 3/4, 1, 1 ½, 2 and 3 inches (made in special conditions over 6 inches.)

Maximum flow: 300 gpm or 62 cubic meters per hour or 1041 liters per minute

Maximum head: 8 times or 80 meters (16 times high pressure series)

Compressed air pressure of the pump starter: maximum 8 times

Diaphragm pump – air pump

Material of diaphragm pump

Pump shell type

Al (Aluminum): For general use

PP (poly

Propylene): For acids and bases: the type of acid and the concentration and working temperature are very decisive.

S.S316 (stainless steel): For all kinds of acids and corrosive substances

AC (Acetal): For a variety of incendiary materials and solvents

KR (PVDF canary): For highly corrosive chemicals and acids

Ductile cast iron: For abrasives and slides

Diaphragm material

Teflon PTFE

Hytrel Hytrel

Santoprene Santoprene

Nitrile Nitrile

Neoprene Neoprene

Kanyar PVDF

Material of one-way pump valve

Diaphragm pumps use one-way valves, hoses or valves. Due to the characteristics of diaphragm pumps in the transfer and movement of various materials, this pump is also used to transfer slippery and abrasive materials. To increase the wear resistance of these parts, metal one-way valves are protected with a thick layer of plastic and liner, or elastomeric materials are used in its construction.

Advantages of diaphragm pump

Advantages of diaphragm pump or air pump

They are very suitable and widely used in cases where the fluid or environment is flammable or explosive.

No mechanical flood and minimum leakage

Pressure and pump head: up to 60 meters

Ability to pump heavy fluids with high viscosity

High suction power

Ability to immerse in fluid

Easy maintenance

Dry operation capability

Ability to suck from barrels and tanks with different dimensions

Ability to control and adjust the flow rate and pumping pressure by changing the air pressure

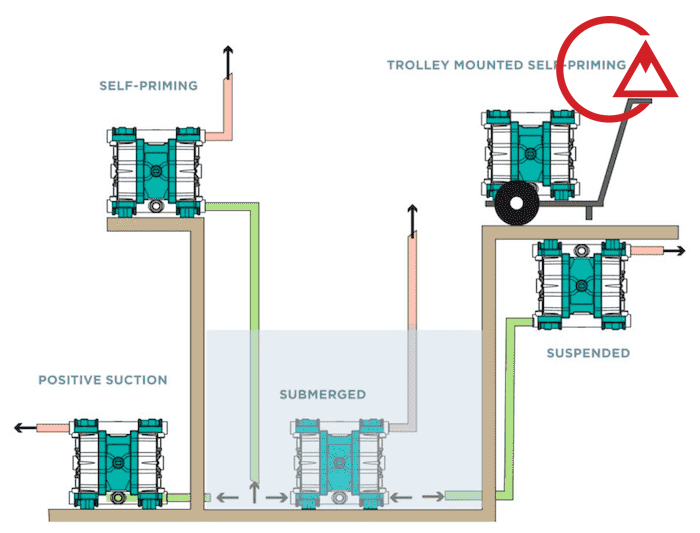

Can be installed above the fluid level, below the fluid level and immersed inside the fluid.

Ability to install in closed environments due to lack of heat generation during work.

Portable and can be installed in different places

How to install a diaphragm pump

Working range

Maximum flow 300GPM or 62 cubic meters per hour

Maximum pressure 8 times

Maximum head 80 meters

Application of diaphragm pump (air pump)

Uses of this product include draining flammable fluids, alcohols, edible and industrial oils, liquefied gases, acids and bases, juices, milk, edible fluids, detergents. Also from these pumps for pumping and transferring fluids and slurries such as ceramic slurries, paints, cement grouts, chemicals, adhesives, resins, petroleum products, drilling mud, mineral concentrate, printer ink, sewage, latex, burnt oil, coating Used asphalt, wastewater, radioactive wastewater, porcelain paste, mineral waste, volatile solvents and explosives and so on.

Can be used for a wide range of dilute and concentrated fluids, corrosion resistant, suitable for flammable fluids, no leakage, etc.

Barrel pneumatic diaphragm pump

Diaphragm barrel discharge pumps can be used to transfer fluids from inside tanks and barrels. The barrel pneumatic diaphragm pump works with compressed air and has a high suction power, and as a result, they are used to pump all kinds of fluids. This type of pump is able to suck fluids up to a height of 8 meters and due to the high variety of production in the body material and diaphragm is used to suck and transfer fluids from inside the tanks and barrels. Also, due to the explosion-proof capability of these pumps, it is very useful for suction and transfer of flammable liquids such as solvents.

Barrel pneumatic diaphragm pump

How to maintain diaphragm pumps

Check and tighten all pump connections periodically to prevent leakage.

The diaphragms of these pumps are most prone to damage, as they are in direct contact with the fluid and are also vulnerable due to their flexibility and must be inspected periodically.

One of the characteristics of these pumps is dry operation, but dry operation in the long run causes damage to the pump and also unnecessary wear of pump parts.

The internal chamber of the pump must be thoroughly rinsed after each use to prevent the destructive effects of the fluid remaining in the pump (depending on the conditions of use of the pump, it must also be sterilized).

Dynamic viscosity table of materials

Viscosity table of cosmetic products

Dynamic viscosity table of cosmetics

Cosmetic products Dynamic viscosity (milliseconds) Temperature (degrees Celsius)

Shampoo 3000 20

Liquid soap 85 60

Toothpaste 70000 40

Hand cream 780 20

Vegetable and animal oil viscosity table

Viscosity table of edible oils

Vegetable and animal oils Dynamic viscosity (milliseconds) Temperature (degrees Celsius)

Castor oil 580 20

Coconut oil 60 20

Corn oil 30 60

Cottonseed oil 60 20

Large oil 30 40

Olive oil 40 40

Palm oil 45 40

Peanut oil 40 40

Soybean oil 60 20

Fish oil 35 40

Pork fat 65 40

Dairy products viscosity table

Dairy products viscosity table

Dairy products Dynamic viscosity (millipascals per second) Temperature (degrees Celsius)

Korea 45 40

Cheese 30000 60

Chocolate butter 50 60

Condensed milk 80 40

Cream (30 to 50%) 15-115 20

Milk 2 20

Whey 800-1500 40

Doogh 150 40

Liquid eggs 150 45

Viscosity table of industrial oils

Industrial oil viscosity table

Industrial oil Dynamic viscosity (milligasgals per second) Temperature (degrees Celsius)

Engine oil 5 30 20

Engine oil 10 50 20

Engine oil 15 130 20

Engine oil 40-15 390 20

Engine oil 40-15 3000 15-

Engine oil 50 750 20

Hydraulic oil 46 120 20

Hydraulic oil 68 195 20

Hydraulic oil 100 300 20

Grace 90 700 20

Grace 140 2700 20

Viscosity table of food types

Food viscosity table

Food Dynamic viscosity (millipegals per second) Temperature (degrees Celsius)

Korea 30000 40

Baby food 1400 40

Brewer’s yeast 370 20

Vegetable soup 430 20

Chocolate Sauce 280 50

Fruit pulp 600 20

Dessert 1500 40

Gelatin 1200 45

Glucose 4300-6800 25-30

Broth 110 80

Jam 8500 20

Malt extract 9

500 20

Mayonnaise 2000 20

Vegetable gelatin 300 40

Juice Concentrate 2500 20

Pudding 1000 40

Salad dressing 1300-2600 20

Apple puree 1500 20

Tomato sauce 1000 30

Tomato puree 195 20

Honey 2000 40

Viscosity table of industrial products

Viscosity table of industrial products

Industrial products Dynamic viscosity (millipegals per second) Temperature (degrees Celsius)

Glycerin 100% 650 20

Varnish (25% pigment) 3000 20

Polyester resin 3000 30

Printing ink 550-2200 40

Resin 7100 20

Glycol 40 20

Latex emulsion 200 20

Paraffin emulsion 3000 20

Liquid wax 500 90

Cleaning emulsion 1500 70

What is a diaphragm pump?

What are the types of diaphragm pumps?

Let us know what you think

Dear visitor, we would like to inform you that unfortunately, due to the abuses committed by some of the visitors of this section, after registering a consultation request, our colleagues will contact you as soon as possible and answer all your requests and questions, dear ones. They will answer by phone and it is not possible to enter a written answer in this section, thank you in advance for your patience and cooperation.

first name and last name