Calibration pot (calibration cylinder)

In various water and wastewater treatment processes and even in other industries, sometimes it is necessary to inject a specific volume of a liquid into another fluid. </= font>Calibration Cylinder

Calibration Cylinder is a precision instrument that is used to inject a specified amount of liquid .Calibration pot (calibration cylinder) is a cylindrical container that can be made of glass, PVC or even steel. The cylinder body is graduated and the amount of injection is determined. By installing the calibration cylinder before the injection pumps, only the specified amount of liquid will enter the target tank. Calibration cylinders are designed and produced in different sizes and materials, and Bhab company provides all technical services in this field.

What is a calibration cylinder?

Calibration Cylinder, which is also known as Calibration Pot sp or calibration container

or graduated injection containe=

r or measuring pot or calibration container , is placed in the instrum=

ent equipment group. In terms of structur=

e, the calibration pot<font= style=3D”vertical-align: inherit;”> is a calibrated cylindrical container whose body may be made of glass, PVC and sta=

inless steel. When a chemical substance needs t=

o be injected into a tank, we determine the exact amount of liquid<f= ont style=3D”vertical-align: inherit;”> using a =

calibration cylinder . For this purpose, t=

he total volume of liquid to be injected in a period of time enters </= font> the calibration pot .=

Since the cylinder is in t=

he path of <= font style=3D”vertical-align: inherit;”> the injection pump</= b> , the suction of the injection pump will be from the tank o=

f the calibration cylinder. In this way, the maximum amount of injected material will be what we enter=

ed into the calibration cylinder. This prevents an additional chemical from entering the tanks. <= /font>Pot calibration</fon= t> ensures that a chemically sensitive substance do=

es not enter the fluid more than the specified amount and in a way validate=

s the injection process. The injection pu=

mp can be a simple pump or precision pumps likeDosing pump=

be

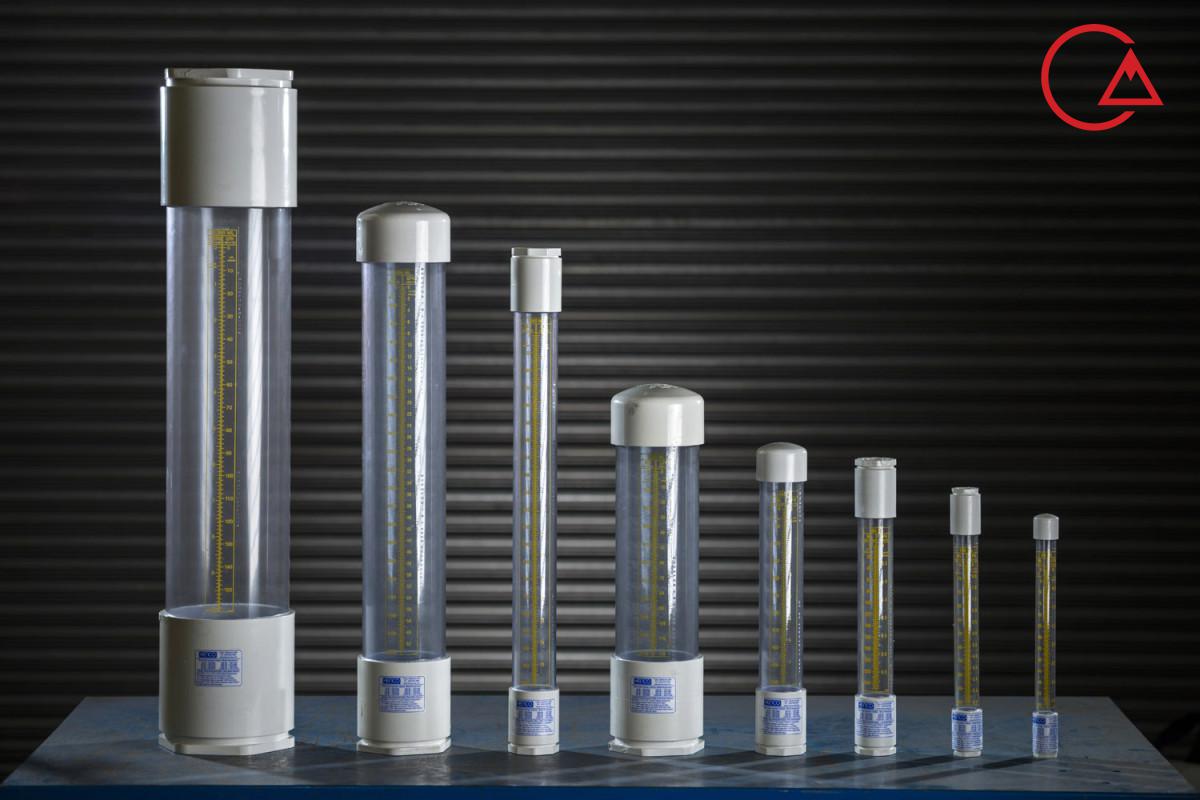

Types of calibration cylinders

Calibration pot can be classifi=

ed based on technical specifications such as body material, capacity and ch=

arging method.

Types of calibr=

ation cylinders in terms of body type</span= >

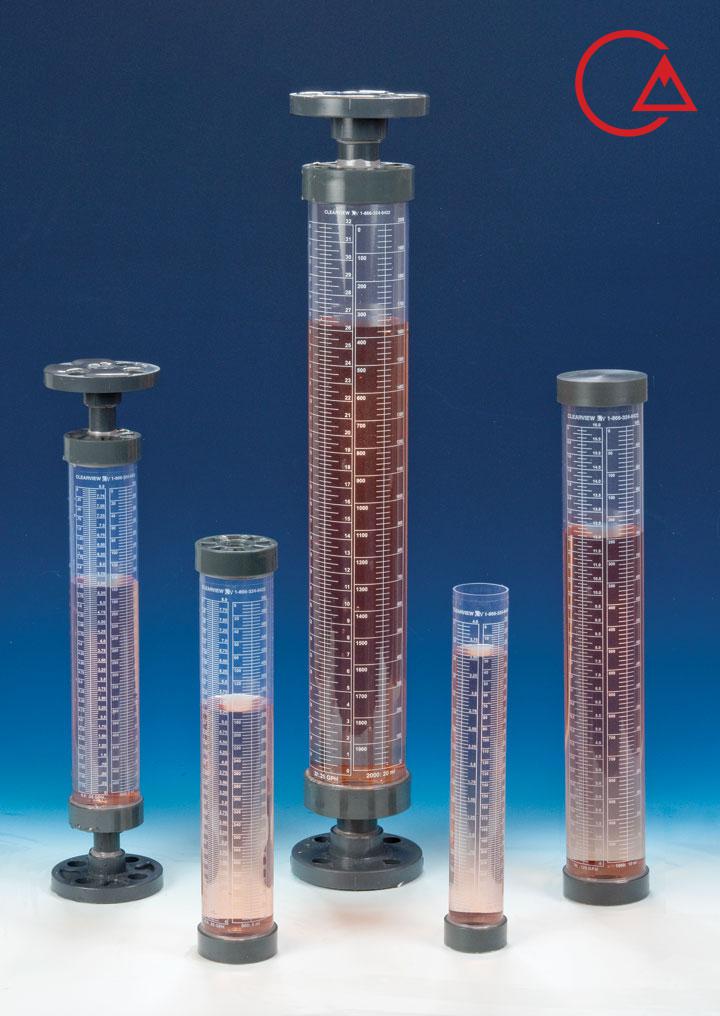

Generally, there are three types of widely used materials for the=

calibration cylinder body: glass, PVC, stainless steel

We choose the material of the body according to the type of chemi=

cal substance that is supposed to be placed inside it, so that it has the h=

ighest resistance to corrosion. Glass is more resistant to chemicals and therefore more wid=

ely used. &nbs=

p;The temperature of the injection material is also influential in choosing=

the body material. If there is a possibi=

lity of being hit, resistant materials such as steel should be used. </font= >The glass body has this advantage=

over the other two options that the contents inside can be seen. <f= ont style=3D”vertical-align: inherit;”>It is also possible to observe the f=

low rate of the injected liquid.

Types of calibration cylinders in terms of charging methods

The calibration pot is placed b=

etween the injection pump and the chemical tank. If the calibration cyli=

nder is installed above the tank, we introd=

uce the chemical into it using a suction pump. Since this method has a higher production cos=

t, this method is recommended only if we have to install the cylinder highe=

r than the tank. The suction pump or vacuu=

m pump used can be electric or manually operated. The suction pump sucks the chemical from the tank an=

d enters it through a tube connected to the top of the cylinder housing.</f= ont>

If the calibration cylinder<= /font> is located below the tank, it can be filled by grav=

ity. It should be noted tha=

t in order to fully empty the tank and apply full pressure, the cylinder mu=

st be installed lower than the bottom of the chemical tank. For cylinders that are filled by gravity, =

a place at the highest point of the cylinder should be provided for air eva=

cuation during loading.

How the calibration cylinder works=

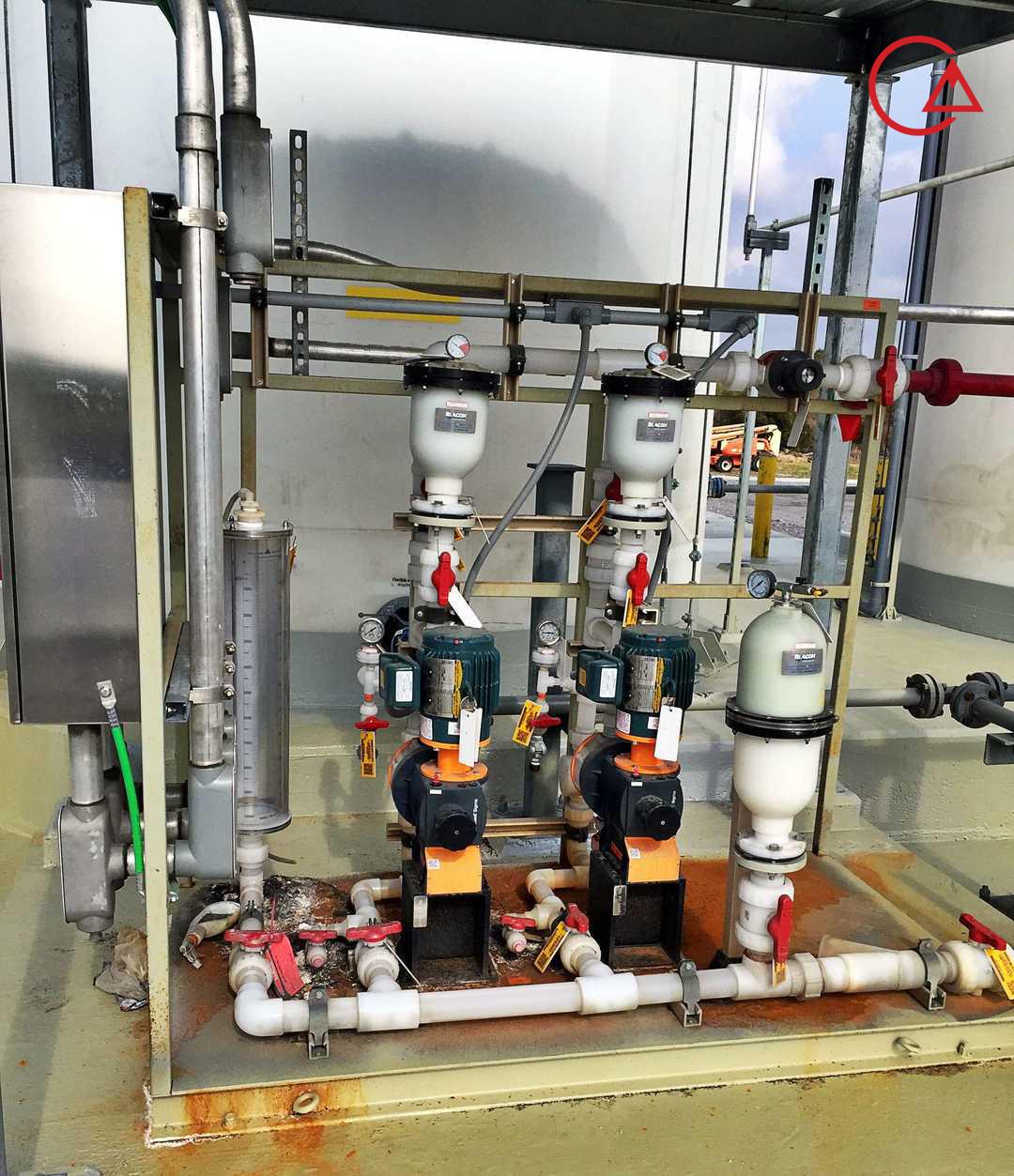

The collection consists of 3 main parts:

- Chemical <b= >reservoir: A storage o=

f a substance that is to be continuously injected. The volume of the tank will be calculated and built=

based on the daily consumption. The material of the tank should be corrosion resistant.= - Calibration Pot </font= >: It is the same as <fo= nt style=3D”vertical-align: inherit;”>the calibration cylinder</= span> , the size of which is determined based on the amount of material=

that must be injected in each work period. <= /b>The cylinder is c=

onnected to the chemical tank through an inlet pipe to be fed through it. <= /font>An electric valve is placed =

in the path of the inlet pipe so that the process of filling the cylinder i=

s done only at the designated times. The cylinder can be installed above or below the tank. <fo= nt style=3D”vertical-align: inherit;”>If the=

calibration cylinder is placed above the ta=

nk, a suction pump is responsible for introducing the chemical into the cyl=

inder. If the cylinder is i=

nstalled below the tank, the process of filling the cylinder is done throug=

h gravity and fluid pressure in the chemical tank. - Injection pump =

: It can be a simple pu=

mp or even a precision injection pump (dosing=

pump) . The pump is installed after the cylinder and is connected to i=

t through a pipe. A valve i=

s located on the way out of the cylinder to the pump to open only when inje=

ction is needed.

The way it works is that by th=

e controller system, the inlet valve to the cylinder is opened and the spec=

ified amount of the chemical substance and only as much as the capacity of =

the cylinder enters it. The=

n the inlet valve is closed to prevent entry. In the next step, the outlet valve of the cylinder is op=

ened and the pump starts injecting. This process continues until the end of the liquid inside the cyli=

nder. When the fluid volume=

is used up, there is nothing left to inject. They usually set specific time intervals for injecting a=

certain volume of chemical substance. When the next period of injection starts, the whole said proces=

s is repeated again. The opening of the inlet and outlet valves may be done automatically by the solen=

oid valve and with the command of the controller, or the process may be per=

formed manually by the operator.

Advantages of calibration pot

- Relatively low cost of production

- High accuracy in determining the amount of injectable liquid</fon= t>

- Low error in determining liquid volume

- Easy installation and setup

- Simple and low-cost service and maintenance

- The possibility of grading based on several units of measurement<= /font>

- Long life

- Ability to produce in different capacities

- The possibility of production with different materials of the bod=

y, suitable for chemical substances - The ability to determine the type of input and output connections=

Design and manufacture of calibration cylinder

The most important thing in makin=

g a cylinder is the material of its body, which should be resistant to chem=

ical corrosion, temperature and impact. G=

lass is generally considered Pyrex. Of course, in most cases, the cylinder is made of a combination of=

different materials:

- The main container is made of Pyrex glass, PVC or steel.<= /font>

- The parts of the upper and lower parts are made of a new type of=

polymer called =

Polyvinylidene Fluoride or PVDF , which i=

s placed in the group of thermoplastics, has high tensile strength, and its=

temperature tolerance range is also very high (-60 to +150 C).</fon= t> - Sealing gaskets and o-rings are made of <spa= n style=3D”color: #993366;”>Teflon &nb=

sp;with the chemical formula Polytetrafluoroethylene or&n=

bsp; PTFE</font= > . - The supporting parts are also made of stainless steel.</f= ont>

Another important point is the cylinder capacity. Usually, we consider the volume of fluid t=

hat is displaced in one minute of operation of the injection pump as the ca=

pacity of the cylinder. If =

the pump is small, the volume transferred during 2 minutes of pump operatio=

n can be considered as the cylinder capacity.

The next thing is the way to charge the cylinder, if it has to be=

done through a suction pump, then a suitable pump and a proper functioning=

structure should be seen for it.

The price of the calibration cylinder</fo= nt>

The cost of the calibration pot</fo= nt> depends on several factors, some of the most im=

portant of which are:

- Body Material

- The impact resistance of the body

- The body’s resistance to heat or thermal shock</li= >

- Cylinder capacity

- How to connect the cylinder to the chemical tank and pump=

- How to charge the cylinder