- The reason why the anti-acid pump is named is their resistance to the most corrosive acids

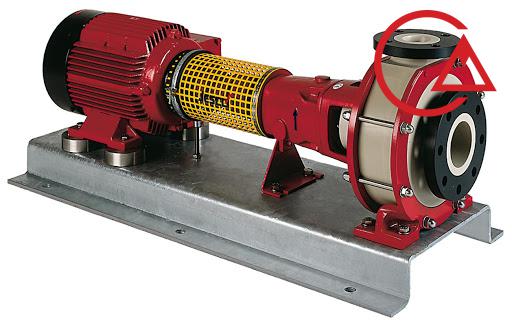

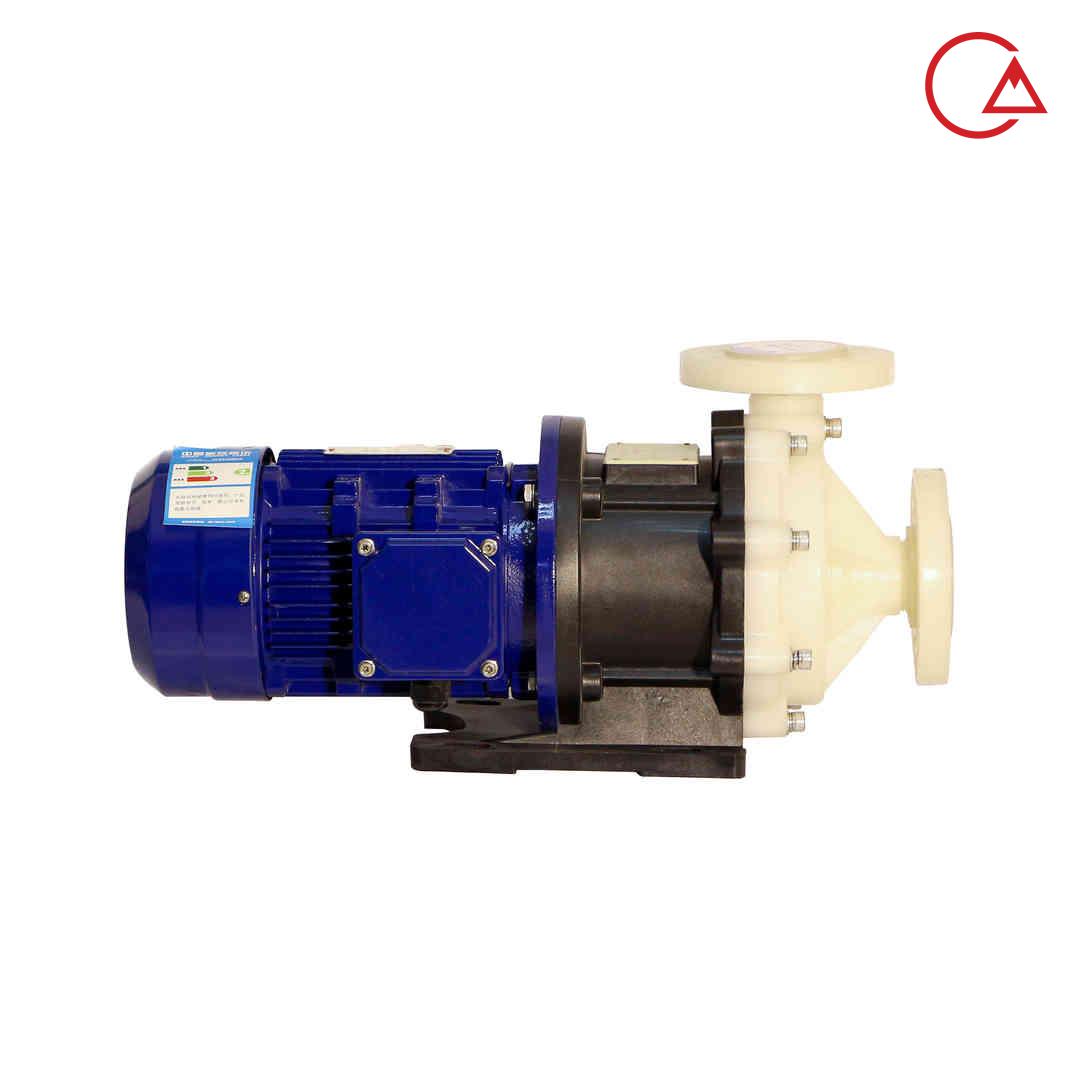

- All pumps are commonly used to move fluids

- Anti-acid pump is used for this purpose like all other pumps

- But with one difference that these pumps show a very high resistance against corrosive fluids

- The fluids moved through the acid pump can be chemical, acidic, solvent, alkaline, etc

- The anti-acid magnetic pump stops fluid leakage into the environment and prevents the wastage of valuable fluids.

- Anti-acid magnetic pump noise is low

- And its structure is designed very simply

- Anti-acid magnetic pump has the ability to pump in a special situation and is considered an excellent option

In simpler language

- Anti-acid magnetic pump is considered as a type of chemical transfer device.

- In these pumps, there are strong motor drives that have screw propellers

- And the suction procedure takes place in their end part. The propellers are placed in a closed or semi-open position

- The reason for distinguishing the anti-acid pump from other pumps is that they are not sealed

- which is used to prevent the leakage of dangerous fluids.

- If you have noticed, mechanical sealing is very important in the pump industry.

- Mechanical sealing and the use of graphite threads cause sealing problems

- And this practice generally creates environmental problems.

- Magnetic pumps are the best option to prevent leakage

- And they solve the problems of mechanical seals to a great extent.

- Most magnetic pumps are in the category of centrifugal pumps

- This product, in turn, has a high value

- and the necessary standards have been used for it.

Anti-acid pump brands that can be supplied and sold

- ProMinent

- Trundean

- Munch

- Argal

Anti-acid pump material

- Acid pumps are made of different materials because they are used to move different types of fluids with different characteristics. The anti-acid pump is usually made of the following materials, each of which is suitable for a type of fluid.

- Polypropylene PP

- PE polyethylene

- PVC PVC

- Teflon PTFE

- Kainar PVDF

Magnetic coupler

- If you pay attention to these pumps, you will not see a direct connection between the electric motor and the pump impeller.

- It has a magnetic field that causes the propellers to move

- This operation is done in such a way that the problem of leakage is completely solved and the mechanical seal is removed. In the seal section of the anti-acid pump, a two-piece shaft can be seen.

- The shaft is divided into two internal and external parts. In the internal part, a set of magnets can be seen

- For each of them, the property of magnetism is precisely provided, and this property causes them to be completely placed on the shafts.

Anti-acid pump manufacturers

- Prominent Germany Company

- Aston company, Germany

- CSE Company

- Debem company

- Jesco Germany company

- Raje Dia India Company

- Trundean Company

- SPC company

- Bahar Pump Company

- Bahman Iran Company

- Dia Company

Important factors in choosing an anti-acid pump

- Liquid temperature

- Height relative to the stage

- Output pressure from the pump

- Pump load factor

- Solids that are suspended in solution or are corrosive.

- Corrosion resistance of metal

- Electrochemical behavior

- Considerations that have been followed in the construction.

Anti-acid pump components

- Acid pump casing

- The impeller is open in this pump series

- The metal shaft of the pump, which is responsible for transferring power from the motor to the magnetic disc

- In these pumps, the impeller is connected to a second magnetic disc, which has an anti-acid coating

- The seal, which has the function of sealing the pump, is different for the acid pump with various uses

Advantages of antacid pump

- Today, the anti-acid pump can meet all special process conditions without the need for

- cover special operational procedures at a reasonable economic price

- These pumps can circulate all kinds of liquids including acids, oils and minerals without any leakage.

- From a process point of view, temperatures up to 850°F (approximately 450°C),

- 3000 (approximately 200 bar) and powers up to 500 horsepower (approximately 400 kW) .

- Another advantage of the anti-acid pump is that it is quiet

Anti-acid pump specifications

- This pump is a type of pump with special conditions

- In this type of pump, if the sealing box has a cooling water part, in packing conditions for liquid temperature of more than 300 degrees Fahrenheit, the bearings have high resistance.

- It has been seen many times that seals are placed in a mechanical state and this is used instead of packing, which causes leakage.

- In some models, a converter is used, which is connected to the part of the pump shell, and in this way it is easier to move.

- The shells are placed in a vertical position.

- These types of pumps are coupled using single-phase or three-phase electric motors, and its inlet and outlet are flanged or threaded.

Installation instructions

- Polymer pumps, like other centrifugal pumps, should never be started dry, i.e. without fluid

- Especially in 3000 rpm pumps, which are destroyed due to the extreme heat of the seal part and pump flooding

- The structure of the anti-acid pump is not such that it can accept dry operation.

- The building type of anti-acid magnetic pump is as follows

- Its resistance to cavitation is also low.

- The advantages of the anti-acid magnetic pump are its low noise and simple structure

- So that it makes its maintenance much easier and prevents the precious fluids in the pump from being wasted

- After installing the inlet and outlet hose of the pump, pour some fluid into the pipe to make sure there is no leakage in the connections.

- When turning on and working the pump, make sure that the impeller rotates in the correct direction.

- After finishing the work and running out of liquid, be sure to turn off the pump for a longer life of the pump and its parts.

- To transfer liquid by pump, use soft rubber hoses and connections.

Mechanism of action of antacid pump

- A set of magnets has been used for the external shaft, which use the magnetic fluxes of these magnets to move the propellers and internal magnets.

- This pump is made of two main parts (polymer pump and electric motor), the main part of this product is the front part, i.e. the pump.

- The water pump part consists of 4 parts, which are: (pump housing, pump impeller, shaft, seal or mechanical seal)

- When the electric motor is turned on, the necessary power is transferred to the pump through the motor shaft

- The pump impeller starts rotating and this rotation creates suction at the pump inlet (suction) and draws the fluid into the pump chamber. After the fluid enters the pump chamber, the impeller rotates the fluid and the fluid starts to accelerate.

- that this acceleration has caused pressure

- As a result, the fluid is pushed out of the pump outlet (thrust) by pressure.

- This type of pump is used in the food, pharmaceutical, etc. industries. These pumps are made in different flow rates and heads to move fluid at different heights and volumes.

- which varies depending on the head and discharge of the electric motor pump. The electric motor used in this pump is single-phase and three-phase.

Disadvantages of antacid pump

- These pumps have a higher price compared to centrifugal pumps

Read more on the website of the surveyor

- Polymer centrifugal pump for pumping all kinds of chemical fluids, solvents, acids, bases, etc. It is made in various materials such as polypropylene, PVC, Teflon, Kaynar.

- The special polymer pump is used for moving chemicals, acids and corrosive materials.

- Depending on the customer’s needs and the model of placement in the circuit, these pumps can have a flange outlet and inlet or a hose head.

Anti-acid pump per ton

- Looking for a pump that can handle acid? T-Mag magnetic drive pumps have a variety of acid pump options. From the lowest HP models to the highest, all T-Mag models can provide you with an acid pump solution.

- Get Acid Pump quotes now!

Or find an Acid Pump distributor near you! - T-Mag offers the following acid pump models and accessories:

- AM series mag drive pump

AM series acid pump

- The T-Mag AM series drive pump consists of three sizes of a Mag Drive pump, 1/12, 1/4 and 1/3 HP. Fractional size for low flow applications looking for a compact and efficient witch pump.

- With a variety of material configuration options, the AM Series Magic Drive Pump will fit well into a wide variety of applications, whether OEM slide manufacturers or continuous process users. The AM Series Wizard Drive Pump can be purchased standard with the motor or purchased on its own as a wet end.

Get Acid Pump quotes now! - T-Mag magnetic drive pumps

- AMX series mag drive pump, AMX series acid pump

- The AMX Series Mag Drive Pump is ahead of the competition with the latest heat dissipation technology and six horsepower ratings. The AMX Series Magic Drive Pump offers some of the highest flow rates seen in the industry

- Finally, this pump increases productivity, reduces operating costs and breakdowns, and provides peace of mind. The AMX Series Mag Drive Pump has six sizes to choose from: 1/2, 1, 2, 3, and two 5 HP options. The AMX Series Mag Drive Pump is available in polypropylene and ETFE and is suitable for almost any application.

Get Acid Pump quotes now!

T-Mag magnetic drive pumps

- T-Mag magnetic drive pump accessories

- Acid pump accessories

- T-Mag Magnetic Drive Pumps has a large inventory of parts and accessories needed

To reduce time

- It is less and supports any repairs needed. T-Mag

- Kai is a leader in the fluid handling industry and we provide the original parts and accessories you need for any Mag Drive pump.

Some accessories

- Includes hoses, washers, expansion joints, VFD monitor and power

- T-Mag has made a name for itself through numerous product innovations and patents

- which allows it to be one of the most reliable mag drive pump distributors in the market today.

- T-Mag is the answer to reliability and cost-effective pumping solutions.

- Get Acid Pump quotes now!

Series specifications

Features of the AM series

- TM1C TM2F TM2G

- HP 1/12 1/4 1/3

- Inlet 1/2″ 1″ 1″

- Outlet 1/2″ 1″ 1″

- Maximum flow (GPM) 9 24 26

- Max Head (FT) 15 33 32

- Motor frame size IEC56 B34 IEC63 B14 IEC63B B14

- Curve charts

- TM1C 50 Hz

- TM1C 60 Hz

- TM2F 50 Hz

- TM2F 60 Hz

- TM2G 50 Hz

- TM2G 60 Hz

Coating material

- Polypropylene reinforced with glass filled

- PVDF (Kinar)

- Carbon reinforced ETFE

- Elastomer options

- Wheaton

- EPDM

- Connection options

union with welding socket (standard)

- BSP theme

- Flange with FF thread

Internal compounds

- Bushing axle cover ring, thrust rear axle ring

- Carbon 995 Al Ceramic Carbon 995 Al Ceramic 995 Al Ceramic

- Rulon 995 Al Ceramic Rulon 995 Al Ceramic 995 Al Ceramic

- 995 All Ceramic 995 All Ceramic Rolon 995 All Ceramic 995 All Ceramic

- Sintered Sic Sintered Sic Sintered Sic Sintered Sic Sintered Sic

Mag Drive Series T-Mag AM pump

- Three sizes of a Mag Drive pump, 1/12, 1/4

- and 1/3 HP is formed. Fractional size for low consumption applications looking for a Mag Drive pump

- It is compact and efficient. Despite the various material configuration options,

- The AM Series Magic Drive Pump will fit well into a wide variety of applications

- Be it OEM slide manufacturers

- or continuous process users. The AM Series Mag Drive pump can be purchased standard with the motor or purchased on its own as a wet end.

T-Mag pumps

- Designed to meet the performance requirements of even the most demanding pumping applications. They are designed and manufactured to the highest standards and are available in a variety of liquid path materials to meet your chemical needs.

- T-Mag Mag Drive pump for transferring acids, alkalis, hydrocarbons, heat transfer oils, liquid gases,

- Toxic and explosive chemicals are ideal in industrial and chemical industries. They are also suitable for pumping low viscosity surfactants, acids and CIP chemicals in the pharmaceutical and cosmetic industries.

- In the food and beverage industry, they are ideal for handling CIP chemicals such as sodium hydroxide, nitric acid, and hydrogen peroxide, and for pumping water treatment chemicals.

- Each product assembled by T-Mag Pumps is manufactured to the highest quality standards. Each Magic Drive pump is functionally tested to ensure correct operation.

Mag Mag series drive pump features

- Click here for a T-Mag image Click

here for an image of our diffuse heat flow path - High efficiency flow design: The geometry of the impeller and its casing is generated through a hydraulic design program. In addition, Computational Fluid Dynamics (CFD) is used to control the fluid flow pattern, thus reducing hydraulic losses and increasing pump efficiency.

- Integrated CAD/CAE system: Using fully computerized design and analysis to aid product development, modern design concepts help T-Mag products reach the highest technical level in the industry.

- High Performance Magnetic Coupling: We use magnetic field analysis to calculate magnetic torque and maximize magnet usage to ensure sufficient torque margin to prevent separation.

Acid pumping

Stomach acid is natural, a valuable chemical in regular digestion. But in excess or in the wrong place, it is a threat, it inflames and irritates the esophagus, usually causes heartburn and sometimes causes ulcers in the stomach and duodenum, the first part of the small intestine.

- People with problems related to stomach acid in various ways.

- proved and otherwise behaved for age equations

- But it wasn’t until the mid-1970s and the introduction of cimetidine (Tagamet) that a treatment made the stomach produce its own acid.

cimetidine

- It was a huge commercial success. By some accounts, this first

- It was block boost medicine. Other drugs in the same class, known as H2 blockers, quickly followed suit

- including famotidine (Pepcid) and ranitidine (Zantac).

- Currently, H2-blocking proton pump inhibitors (PPIs) are the most commonly used drugs for problems associated with decreased

Acid level

- The stomach is relieved, reduced

- PPIs include many well-known brand-name drugs such as

- Prevacid (lansoprazole), Prilosec (omeprazole) and Nexium (estrogen).

- . They are prescribed to prevent and treat ulcers in the duodenum (where most ulcers occur) and stomach.

- They also deal with various problems that occur when stomach acid backs up into the esophagus

- Which – if it happens regularly – is a complication called gastroesophageal reflux disease (GERD).

- In most head-to-head trials, PPIs have been shown to be superior to H2 blockers.

Overall

- , billions of dollars are spent on PPI every year. In the US, a year’s supply of one of the cheaper types, which includes generic omeprazole and over-the-counter Prevacid, costs about $200. If one were to pay full price for the more expensive PPI, the annual cost would be at least 10 times that amount.

- Reducing the level of stomach acid is not one of the glamorous jobs of medicine, but it is a yeomen job, so PPIs are generally considered a success story: safe (more on that just below), effective drugs that are the source of many of the system’s discomforts. They target digestion.

The Human Body

- But, now, some doubts are involved about PPI. These concerns fall into two broad categories: overuse, and drug interactions and side effects.

- For GERD relief, it is good

to visualize the esophagus and stomach from GERD inflammation - Many people take PPIs for gastroesophageal reflux disease (GERD). By reducing stomach acid levels, they reduce acid reflux in the esophagus and heartburn symptoms.

excessive use

- It is reasonable to take PPIs if you have problems with stomach acid or the possibility of illness. But the occasional case of heartburn does not require PPI treatment. For this type of spot duty, the old staples of over the counter medications like Tums, Rolaids, and Maalox will likely work just as well, as will any of the H2 blockers.

- In fact, it takes a few days for a PPI to have a full effect on acid secretion, so an H2 blocker may be more effective for a mild, short-term problem with stomach acid. However, people often take PPIs under the mistaken assumption that they are taking better drugs. The fact that omeprazole is available as a generic,

cost difference

- has reduced, but you still want to pay more for PPI,

- And it definitely is if you buy one of the more expensive brand name varieties.

- If the problem is heartburn, there are also changes

- That can help you not include anything.

- The commercials are true

- Tackle a big meal

- It can give you heartburn, so eat smaller meals

- can help solve this problem. You can also cut down on alcohol. And if you are heavy

- GERD and heartburn are on this very long list of problems

- which decreases and even if you lose weight you can even lose it.

Pump changes

- PPIs available in the US generic brand name dexlansoprazole

- Estrogen fattening Nexim is closely related to Omeprazole

- Lansoprazole is available as a generic

- Omeprazole Prilosec is available as a generic

- Omeprazole, immediate release, with sodium bicarbonate

- Protonix pantoprazole is available as a generic

rabeprazole Aciphex

- It may work faster Note that all generic names end in -prazole.

- Drug interactions and side effects At first, there were concerns that it might

- PPIs increase the risk of stomach cancer . These concerns were unfounded, but others have taken their place

- Partly because people often take PPIs on a daily basis ,

So

The amount of total drug exposure is quite significant.

Here are some of the drug interactions and side effects that cause concern:

- Interaction with clopidogrel

- Clopidogrel

- It is sold as Cervovin Clopillate and Plavix

- which prevents the formation of blood clots

- And it is often prescribed by people with heart disease to prevent heart attacks

Application of magnetic pumps

- In cases where the pumped fluid is dangerous or expensive

- And the pump must not leak under any circumstances

- or the amount of leakage should be as low as possible,

- Magnetic pumps are used.

Among the applications of this pump, it can be mentioned to transfer the following materials:

- Toxic or expensive materials

- Volatile chemicals

- Corrosive fluids

- Dangerous liquids for the environment

- Radioactive fluids

Advantages of magnetic pumps

- High safety in transmission

- Capable of pumping edible substances and toxic fluids

- Optimization due to the elimination of mechanical sealing

- No need to change the mechanical seal

- No leakage

- Reduce pump depreciation

- Easy maintenance and simple construction

Disadvantages of magnetic pumps

- Costly

- Inability to transfer abrasive materials

- They do not work dry

- Low resistance to cavitation

- Heating of the pumped fluid

What is the mechanism of magnetic pump or magnetic pump?

As shown in the figure below, the impeller must be rotated to pump the fluid. This rotation in normal centrifugal pumps is done directly by the rotation of the electromotor shaft, but in magnetic centrifugal pumps, the electromotor shaft first rotates the magnetic rings and then the rotation of these rings rotates the impeller.

Products

Acid transfer pumps

ISO logo

ISO logo

certified ISO 9001:2015

MAXP SERIES-MAG driving acid pump

ANSI

Excellent for high temperature service

Max Flow: 2000 GPM

Max Head: 470 ft

Temperature: -150°F to 800°F

Magnetic Drive MAXP pumps are designed to fully meet ANSI B73.3 standards. Its rugged construction and proven design features make it ideal for use in chemical facilities.

More information

Quick quote

MPL/MP drive acid pump MAG series

SUB-ANSI/ANSI

Excellent for high temperature service

Maximum Flow: 150 GPM

Maximum Head: 190 ft

Temperature: -112°F to 660°F

MPL/MP Series – Mag Drive Pumps An efficient and reliable choice for compact applications With medium flow, they are medium to high. The process side of MPL series pumps conforms to ANSI B73.3 dimensions.

More information

Quick quote

MAG series MPH drive acid pump

Excellent for high temperature service.

Max Flow: 150 GPM

Max Head: 190 ft

Temperature: -40°F to 535°F

MPH Series – Mag drive pumps designed for low flow, medium to high head and high temperature applications. MPH series pumps save valuable space and eliminate alignment problems.

More information

Quick quote

MAG drive acid pump MEP series

Max Flow: 106 GPM

Max Head: 103 ft

Temperature: 175°F

MEP Series – Medium magnetic drive thermoplastic polypropylene pumps designed for chemical transfer applications. Simple construction makes for affordable initial cost and ease of maintenance.

More information

Quick quote

MMP series MAG drive acid pump

Max Flow: 20 GPM

Max Head: 95 ft

Temperature: -112°F to 536°F

MMP Series – Sealless, Mag Drive, Centrifugal, heavy-duty pumps with superior bearing materials for very low flows . These coupler pumps are closely similar to the MP/MPL series.

More information

Quick quote

Acid pump drive CHEMSTEEL SM SERIES-MAG

Excellent for high temperature service.

Maximum Flow: 30 GPM

Maximum Head: 110 PSI

Temperature: 450°F

Chemsteel SM Series Magnetic Drive Pumps are designed to handle corrosive liquids that require pumping up to 150 psi. These pumps are manufactured with very precise tolerances.

More information

Quick quote

Acid pump drive CHEMSTEEL S SERIES-MAG

Excellent for high temperature service

Maximum Flow: 30 GPM

Maximum Head: 150 PSI

Temperature: 450°F

Chemsteel Series S – Magnetic Drive Pumps are designed to handle corrosive liquids that require pumping at pressures up to 150 psi. These pumps are manufactured with very precise tolerances.

More information

Quick quote

Drive acid pump MPT SERIES-MAG

Max Flow: 40 GPM

Max Head: 440 ft

Temperature: -22°F to 445°F

MPT Series – Mag Drivre Sealless Vane Turbine Pumps are specifically designed for small flows at high heads. The MPT series has a structure similar to the MP series.

More information

Quick quote

MTA series MAG drive acid pump

ANSI

Maximum Flow: 320 GPM

Maximum Head: 285 ft

Temperature: 5°F to 275°F

The Texel® MTA Series is a sealless, mechanically bonded, molded PFA liner that is thicker and more uniform than most rotomolded liners. Ideal for high purity applications

More information

Quick quote

Drive acid pump ME SERIES-MAG

Max Flow: 90 GPM

Max Head: 140 ft

Temperature: 32°F to 195°F

Working Pressure: 70 PSIG

Texel® ME Series Magnetic Drive Pumps are reliable and durable. They are the solution for low to medium flow corrosive fluid applications.

More information

Quick quote

MAG drive acid pump MST series

ANSI

Max Flow: 140 GPM

Max Head: 260 ft

Temperature: 250°F

MSTS Series – Magnetic Pumps Extremely rugged design, virgin PFA injection molded housing, non-sealed SiC back cover, designed to ANSI dimensions. The rear cover can be washed for solids.

More information

Quick quote

MAG series 3596 drive acid pump

Maximum Flow: 5000 GPM

Maximum Head: 720 ft

Mechanical Seal

Temperature: -350°F to 700°F

Heavy-duty, rugged, universal quality ANSI process pumps that meet the latest ASME B73.1-2001 standard (revision of ASME B73 .1M-1991) have been made.