Avoid the blowout

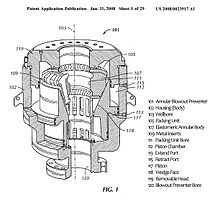

Drawing patents stack BOP Valve eruption stuck under the sea (with Legend)

Avoid explosions ( BOP ) (pronounced with a BOP, not “bop”) [1] a valve specialized or mechanical device is similar to that for sealing, control and monitor oil and gas wells to prevent the eruption of publishing indiscriminate crude oil or natural can be used. Natural gas from a well they are usually in a stack, the valves, the other are installed.

Avoid explosions to deal with the pressures of irregular extreme, and the flow of uncontrolled ( blow forming ) is a tank, the well during drilling stems, etc. have been made. Kicks can lead to a event is potentially catastrophic, be that as blast, known to be. In addition to pressure control wells (in the hole drilling) and the flow of oil and gas, prevented from eruption can be, to prevent the outflow pipes (for example, pipe drilling and well casing), the tools and the drilling fluid from the hole, the well is considered. As well as holes to be known., the hole that the tank can be ended), when a blast is threatened. Avoid the blast for the safety of the crew., the rig (the equipment system used to drill the well) and the environment, and for the monitoring and maintenance of the integrity of the well is very important. Therefore, to prevent an eruption, to create safety downtime for the system that contains them, they disappear. have not been considered.

The term BOP in slang, oil field to refer to avoid the eruption will be used.

The term stands for prophylactic ( preventer ), usually with a type (e.g. ram preventer ), it can be, for referring to a unit, avoid the blast can be used. It is also possible to simply type it (e.g., RAM) to a preventive eruption point to be. Jargon, avoid explosions, stack, preventing the eruption of the system and prevent the explosion of the usually interchangeably, and generally to describe a collection of several prevents the explosion of accumulated with the kind of performance as well as the components of the auxiliary are used. A typical system prevent the eruption of deep water under the sea, includes components, such as lines, electrical, hydraulic, etc. sheath of control, battery, hydraulic, Valve test, lines, and valves, alluring, and suffocating, connect, lift, etc., fasteners, hydraulic and a frame supported.

Two categories of بادگیرها the most common are: RAM and annular . پشتههای BOP, often from both types of use, usually at least a BOP annular above several Ram BOP is accumulated. In Wells, ground, etc. masts Marine and potholes submarine of the tools prevent the explosion of the use. BOPهای terrestrial and submarine at the top of the well that the well is famous for the sturdy they are. BOPها in offshore platforms below the deck, masts are installed. BOPهای submarine is a رایزر drilling that way steadily for field drilling fluid emitted from the Wells provides to rig offshore at the top are connected. In fact, a رایزر hole wells up rig expands. Preventive blast always function properly, don’t. An example of this eruption, Deepwater Horizon, in which the pipeline that of BOP passes a little bent, like BOP failed tube would not interrupt.

The importance of using Valve eruption stuck (Blowout Preventer)

Prevent an eruption in a variety of styles, size and grading of pressure there. Several separate units that various functions are doing to create a stack, preventing the explosion are combined. Several Prevention of eruption of a type often used for redundancy to be provided, which is an important factor in the effectiveness of the devices is secure .

Basic actions of a system, prevent from explosion are:

- The liquid well into the hole of the well restrict .

- A tool to add liquid to the water to provide.

- Let the volume, control the fluid from the hole, the well withdrawn.

In addition, and in doing so, it functions the primary. this system avoid the blast for the following can be used:

- Set and monitor the pressure of the well, and …

- Put and hang . The drill string in the center of the well

- In Wells close (for example, empty space, etc., rings, etc. between the drilling tube and cover to close).

- “Kill” of the well (prevent the flow of fluid formation, etc. bashing, etc. from the tank to the inside of the well) .

- To close the openings of the Wells (the wells close).

- Disconnect . Casing or drill pipe (in an emergency)

In drilling a well, a typical high pressure, fields, digging through a stack, preventing the eruption to the side of the oil tank and the gas conductivity are. As drilling well used. the drilling fluid, the “flower” through the strings dig into the side of the drill, the “blade” driven from the hole of the well cavity ring shapes, circular, etc. between the exterior of the drill pipe returns. And cover (the tube that hole Wells covers). Column drilling mud hydrostatic pressure to deal with the pressure of the opposing formation drilling downward applies and to continue drilling permits.

When a kick (influx of formation fluid ) occurs, etc. operators rig or automated systems units prevent the eruption of the can; and ring, sealing understand the flow of fluid out of the hole, well, stop. Then the flower denser into the hole of the well to the bottom of the drill string, etc. to the side of the annular gone up and through The چوکها (محدودکنندههای flow) through line choke at the base of the stack BOP is outside the pressure of the well overcome to be. When the flowers “deadly weight” from the bottom of the well to the top, spread, etc. of Wells “was killed”. If the integrity of the well, be healthy, etc. drilling may be resumed. From the other side, if blood circulation possible in … May be well with ” the bullet out, ” ruined, and to force flower heavier from the top through the connection line killing at the base of the stack, the pump will. This is due to the pressures of a higher level, which probably required, and the fact that many of the flowers, in principle, in the ring, have forms acceptor, in part, an open hole below the deepest hot shoe cover is less desirable.

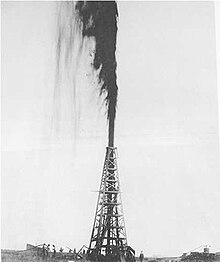

If the barrier of the eruption, and mud pressures facing up a hit to limit the present. eruption led to the firing potential of the tube, oil and gas from the hole of the well can be left to rig damage and the integrity of wells to the following question .

Since the BOP for the safety of the crew and natural environment, and also the drilling rig and water well are important, etc., authorities recommend, and regulations required that the BOP regular inspection, the test and renewal are. Tests of daily testing, research, potholes critical ranging tested monthly or less on The چاههایی with low probability problems, the control is different.

Tanks, reliable operation of oil and gas are increasingly rare and are out of reach, which leads to the increase in exploration wells, deep water, under the sea can be and need that BOP, up to a year in extreme conditions stay underwater [ need source ] . In conclusion, collections BOP bigger and heavier, they have (for example, a unit BOP Valve eruption stuck from the types of the RAM can be more than 30,000 pounds of weight have), while the space اختصاصیافته for پشتههای BOP in the masts, Marine, existing growth متناسبی is not. So the key focus in the technological development BOPها in the past two decades, limiting the footprint and weight of them and the simultaneous increase in operational capacity, the safe had been.

A variety of Valve erupted stuck (Blowout Preventer)

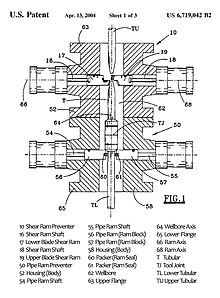

BOPها in two main types of ram and annular are . Both are often together in the drilling rig پشتههای BOP Valve eruption stuck are used, etc., usually with at least one BOP, annular, which backs of several of the Ram BOP cover.

Prevent the explosion of Ram

The Ram BOP Valve eruption caught by James Smither Abercrombie and Harry S. Cameron in 1922, was invented in 1924 by Cameron Iron Works was released . [3]

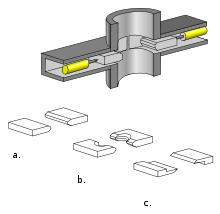

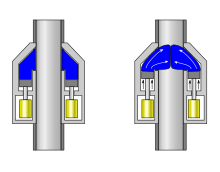

A lion eruption stuck BOP of the type of RAM in terms of performance, similar to a gate valve is a pair of piston steel clip. the RAM uses. Rams to the center hole Wells stretches can recover up to stream limited live or in order to allow the flow are opened. The inner surface and the top of the RAM with the package are (sealants elastomeric) is embedded that to each other. the hole of the well and around the tube that hole Wells is going on. force. Output in the sides of the compartment (body) BOP to connect to the lines or valves, choking, and stretch is used.

Rams, or RAM blocks, tap the eruption caught the four common types are: pipe, blind, etc., cut the blind .

The Ram pipes around a drill pipe are closed and the flow in the ring (the space of the ring-shaped between objects concentric) between the exterior of the drill pipe and the hole, Wells, restrict, but prevents flow in the inside of the drill pipe are not. The Ram pipe with holes of variable can pipe in a wider range of diameters ratio of External to the Ram pipe Standard place up, but usually with some loss of capacity , pressure, and longevity. If the pipe in the hole exists, a Ram tube should be closed.

The Rams, Blind (also known as the Rams, sealing, also can be known) that no hole for the tubing, do not, can when the well has a threaded drilling or other tubes, and … well, the power of it, sealing them.

ROM shear for cutting the pipe in the well and sealing synchronously hole well designed.

Has a steel blade for cutting tubes and sealant for the sealing ring after cutting the pipe.

Rams shear Blind (also known as rom the water strap shear or rom shear sealing, also can be known) for the sealing of the well, even when pierced by a drill string is occupied, and slice through the drill string during the closure of the Ram in the Wells is considered. The upper part of the drill string cut from the Rams will be free, while the lower part may be folded, and the “fish tail” to be taken to the drill string from the BOP hang be.

In addition to the functions of the RAM, standard rom, the tube with the hole variable, often referred to as the ram, the pilot-in-one device, preventing the eruption of the amendment made to the name of the Valve test stack is used. Valves test stack in the bottom of a stack BOP fall against the downward pressure resistance, they (unlike the BOP that against the pressures of the upward resistance of the work). By closing the Ram test and a Ram BOP, Valve erupted stuck around the drill string and put pressure ring, a BOP for the proper performance under the pressure of testing being placed.

Rome, Valve, eruption stuck BOP early 1920s, handheld devices, simple and rugged, with a minimum of parts were.

Compartment BOP (body) has a hole, vertical wells, and holes Rams horizontal (compartment guide the Rams), respectively. Rams opposite (piston) in the cavity of the Ram horizontally, have been translated by Shaft Rams threaded housewife (rods, pistons) method learns activated. Torque resulting from twisting شفتهای Rams by a wrench or carts to move the linear conversion is one kid of the goats that to the end of the inner bar of the Ram are connected., the hole of the well, open and closed universes. Such an operation of the type of jack screw mechanical advantage enough for the Rams to overcome the pressures of the bottom of the well and sealing Wells provides.

Rams hydraulic BOP in the 1940’s were used. Avoid the eruption of the hydraulic has potential benefits so many. The pressure can be in the cylinders, hydraulic, opposed against the village and causes the Ram to coordinate their operation. Stimulate relatively fast, and the remote control was facilitated and Rams hydraulic well for Wells, high pressure were appropriate.

Since the BOP for safety and reliability as they are dependent on.

Efforts to minimize the complexity of the devices to ensure the longevity continues to be handled. In conclusion, despite the demands of growing on them. BOPهای advanced, Rome, conceptually similar to the first models are effective, and in many ways to those units similarities.

RAM BOP for use in applications water deep into the world of stimulation and hydraulic uses. شفتهای رزوهدار often still as bars lock that the Rams after stimulation, hydraulic in your position hold, in BOPهای Rams hydraulic criteria. With the use of the lock mechanism, Rome, mechanical, etc. no need to maintain the hydraulic pressure is not fixed. Depending on the manufacturer, bars, locks, it is possible to the shaft of the Ram are connected or not. Other types of locks, the Rams, like the locking wedge is also used.

The set of stimuli typical of Rome (system operator) with caps, removable compartment BOP sturdy they are. Open the hood of the compartment, the possibility of maintenance of the BOP provides and replacement of the Ram to facilitate. Thus, for example, can be a BOP ram pipe to a BOP ram shear blind turns out.

BOPهای ram type shear to the greatest force the closure of the need tube, occupied well cut up. بوسترها (actuator hydraulic auxiliary), often at the end of the outer actuator hydraulic BOP installation are shearing force extra for rom shear provide. If a situation happens where the Rams, shear enabled, the best practice for drilling, this is twine with a distance from each other up to ensure that the Rams are the body tube, drilling, cutting, make up, etc. instead of having a connection tools (metal is much thicker) across the drilling pipes. The Rams, shear

Ram BOP, usually any design are that the pressure of the well to keep the Rams in the closed position and sealing can help.

This is to allow liquid to pass from a channel in the RAM and exert pressure at the rear of the RAM and to the center of the well is achieved. Create a channel in the Ram also the force of the thrust needed to overcome the pressure of the wells to the limit.

BOPهای single RAM and double Ram are usually available. The names to the amount of holes, RAM (equivalent to the amount of effective valves) contained in the unit refers. A BOP, double Ram فشردهتر and lighter than the backs of two BOP, single RAM, while the performance of the same offers, and so in many applications it is desirable. BOPهای Ram trilogy are also manufactured, but not as much as usual.

The development of technological ram BOPها to the potholes push deeper and … more reliability, reduced maintenance, facilitated replacement of components, facilitated intervention, consumption, RÖV, reducing the hydraulic fluid and improve کانکتورها, etc. بستهکنندهها., the SEALs, locks and rooms have been guided. In addition to this, the curb weight and footprint BOP concerns important to consider the limitations of existing rig.

پرظرفیت the most impede the eruption of the Rams, with a big hole in the market, until July 2010, the EVO 20K BOP Cameron, has the air pressure keep up to 20000 psi, the force of Rome over 1000000 pounds, and the diameter of the hole of the Well 18 inches. .

Valve erupted stuck (Blowout Preventer) annular

Invented prevent the eruption of the annular by Granville Sloan Knox in 1946 . Patent of the United States for it, and in 1952 was awarded. [4] often around the rig to the name of the original manufacturer of this device, the “Hydril” is called.

A barrier from the eruption of the type, spacers can be around the drill string, etc. the body or an object, non-cylindrical, such as the overall closed . Drill pipe include fittings tools with larger diameter (threaded connections), and can be made with precise control closing pressure hydraulic through a protective circular “naked” will (i.e., vertically move the alliance, while the pressure on under there). Avoid the eruption of the circular also keep the seal around the tube, drilling, even when during drilling, spins, and effective. The regulation usually requires that a protective circular grasping hole wells to fully close, but محافظهای annular usually the size of محافظهای Rams in maintaining a seal on an open hole are effective. BOP Valve eruption stuck annular usually at the top of a stack BOP are, with one or two prevents circular that on top of a series of several barrier of ram are located.

Avoid the eruption of the annular of the principle of a wedge to closure in the hole, Wells uses.

Has sealed rubber like donuts that as packing unit elastomeric known and gear, steel reinforced. Packing unit in the compartment BOP between the head and piston hydraulic is located. When the piston is activated, drift upward packing unit have that like a sphincter-shrunk and ring or hole, opening, sealing it. Preventive annular only has two parts movable, piston and packing unit, the Are, which kept them in proportion to the Prevention of Rome simple and easy.

The main types prevent the eruption of the annular of the piston “wedge” (on the cone) uses. With the rise of the piston, move the vertical packing unit by head gets bound and Page steep piston packing unit inward, to the center hole of the well compacted.

In 1972, etc. Ado N. Vujasinovic a patent for a change in the shielding annular, known as prevent the eruption of spherical, which is due to the globular head of it to this name can be read, etc. received. [5] as the piston goes up, etc. packing unit upwards against the head of the curve driven, the packing unit to the inside of the retractor does. Both types of پیشگیرنده annular common.

Control methods Valve eruption stuck (Blowout Preventer)

When Wells on land or in the water very shallow, drilled, are, where the head well above the water line is BOP with hydraulic pressure from a stacked remotely activated. Multiple station control around the rig will be installed. We can also identify them by twisting the schools چرخمانند were manually closed the village.

In operations offshore, deeper, with the head of the well just above the line of flowers on the floor of the sea, the five main ways to control a BOP there. Tools may include: [ citation needed ]

- Signal control hydraulics: from the surface through a banana hydraulic sent.

- Signal electrical control of the surface through the control cable sent.

- Signal control audio: from surface, based on a pulse voice modulated/encrypted posted by the converter under the water sent .

- RÖV intervention : vehicles remote (ROVs) to the mechanical valve to control, and not the hydraulic pressure to the stack (through the panels “Hot stab”) can provide.

- Switch dead man / auto cutter: activate safe BOP selected in an emergency and in case of disconnection of lines, controls, electrical and hydraulic.

Two pod control on the BOP valve eruption stuck for redundancy is provided.

Control of the electrical signal sheath is the primary. آکوستیکال, etc. the intervention, RÖV and control the dead man are secondary.

A system/sequence cut emergency or EDS., the rig from the well in an emergency separates. EDS also intended that automatically switches the dead man, to activate it. that valves, BOP, etc., kill and choke closes. The EDS may be a sub-system of the pod, control stack, BOP, or separately, is. [ Citation needed ]

Pumps on the rig usually push through the hydraulic lines to the stack prevent the explosion of the import. آکومولاتورهای hydraulic on the stack BOP are, even if the stack, BOP, rig, isolated it. blockers erupting into space. It is also possible closure BOPها automatically based on the high-pressure or over-current active. [ Citation needed ]

Also, it may be necessary potholes single along the coastline of the United States has the BOP with voice control, backup have. [ Citation needed ], the general requirements of other countries, including Brazil, for the requirement this method was traced. [ Need quotes ] BOPهایی that has these methods are possible to 500,000 U.S. dollars more than the ones that this feature will remove them. costs. [ Citation needed ]

The eruption of deep water هورایزن Valve eruption stuck (Blowout Preventer)

This section needs to be updated . Please update this article to help recent events or new information available to reflect. ( January 2021 ) |

During the Deepwater Horizon explosion of the drilling rig on April 20, 2010, etc. avoid the blast should automatically active group. field drilling to cut off the water sealing worked up from the explosion and oil spill, the next in the Gulf of Mexico to prevent, but failed to fully engage. . Robots, underwater (RÖV) later to set up manually پیشگیرنده Rams, shear blind use were useful, did not.

Until May 2010 was unknown why avoid the explosion failed. Surveyor senior John David فورسایت of the Bureau of shipping American in hearings before the joint research, [7] of the management services minerals and the United States Coast Guard, in the case of investigating the causes of the explosion that his agency last inspected the exploded rig in 2017 testified. 2005. Representatives of BP suggested that the prophylactic may suffer hydraulic leaks is. [9] imaging gamma-radiation from پیشگیرنده that in the 12 and 13, 2010 was carried out. showed that the valves of internal پیشگیرنده to some extent was closed and the flow of oil to make limited changes.

Whether the valves are automatically during the explosion are closed, or manually by the work vehicle is remotely have been closed, etc. is unknown.

A statement that by Bart استوپاک representative, Congress, released, showed that, among other issues, systems, and disconnect the emergency (EDS) as it was intended action is not, and may be due to the explosion on the Deepwater Horizon, suffered a malfunction is. [10]

License Macondo Prospect by management services minerals in the year 2009 does not need to control devices the acoustic extra no.) With the success of the package are not RÖV up, since that BOPها with manipulation under water ( intervention, the expected results of a survey complete, it is unclear whether the removal of a factor in the explosion has been or not.

Documents that during the hearings, the Congress on 17 June 2010, discussed, etc. indicate that the battery in the pod control of the machine is empty, and the owner of a mast Transocean “change” is. possible equipment Cameron for the site ماکوندو (including guided false hydraulic pressure to a valve experiment, rather than a tube BOP ram accumulated below), who, despite the warnings of the contractor, they are in this case, the risk of downtime BOP increases. Another hypothesis was that a connection in the pipe, drilling may be in the stack, BOP to be located in such a manner that the Rams shear, it has a thickness of not passing from the material to slice them.

It was later revealed that the second piece tube at some point during the incident ماکوندو enter the stack BOP Valve eruption was stuck and potentially the malfunction of the cutting mechanism BOP explained.

From July 2010 was unknown whether the tube may be through well come out or not, probably of the drill pipe is broken that the inside of the well is. The final report, DNV, showed that the second tube portion of the drill string is then cut by scissors retardant wind is out.

July 10, 2010, the BP operation, install a cap sealing, etc., as well as Stack capping, etc. at the top of the stack prevent the eruption failed to start. Based feeds video BP of the operation, set cap, sealing, etc. to name tops hat 10, including a stack of three wedges shear blind BOP, be that by Hydril (a oil and Gas Company (GE) is one of the main contenders, Cameroon, etc. were produced. Up to 15 July, stack 3 Rome for the first time in 87 days. ماکوندو it. if only temporarily, to a good seal will.

The United States government wanted in the event of any change of pressure when the intersection of Wells, relief wells with happen, protective failed replaced. On 3 September 2010, in time 1:20 p.m. CDT, the 300 tons of stunts, explosion, failed from the Wells was removed and gently to the surface of the Earth was. Later in the same day, a protective alternative on the well was placed. On September 4 at 6:54 pm CDT, etc., prevents the explosion failed to water level reached, and the hours of 9:16 pm CDT in a special container on the vessel Helix Q4000 was. Avoid the explosion failed to check by Det Norske Veritas (DNV) to a center of NASA in Louisiana was.

On March 20, 2011, the DNV report to the Ministry of energy, the United States offered . The primary result of them was that, while the Rams are managed to some extent through the drill pipe, cut up, but did not make the hole sealing because they drill pipe, line of action desired, the Rams are کمانیده was (because the drill string in a clamp was stuck. Connect the tool in the ValveBOP annular upper), the scissors will block and makes the stimulus, shearing the drill string to be able to provide enough force to complete the move, not and tubes, cut up and water sealing it. They have no downtime activation due to a defective being, the battery, the proposal did not. The upper part of the inhibitor of blowing due to oil spills, numerous that the performance of the hydraulic actuator in danger, according to the design apart, did not, and this must be during the recovery separated was.