Electric motor’s three-phase 355 kW 480 horse <p”>Has 18 months warranty, in the event that the objection from the…

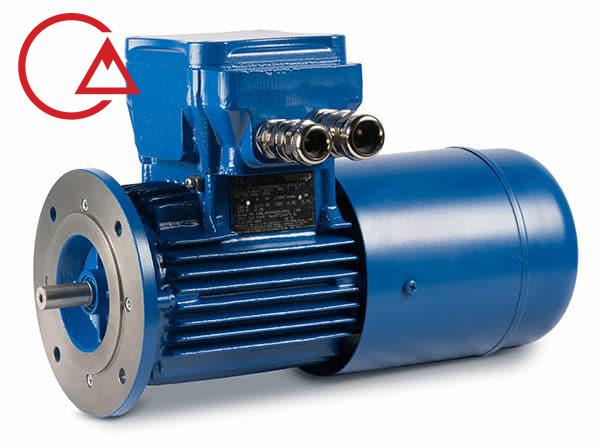

Electric Motor

Buy an electric motor

To buy an electric motor , you must first determine your need to use it. For example, if you plan to have the electric motor for household or small jobs, you may be able to use smaller motors with less power. But if you plan to use it for industrial and heavy work, you need more power. In order to buy the best electric motor, it is better to collect the necessary information about it before buying, and according to your needs, get more information from the sellers about the models, brands, powers and various features of the motors. Among the most important influencing parameters in buying an electric motor, the following can be mentioned:

Buying an electric motor based on power

Power is a very important characteristic for choosing an electric motor, which determines the dimensions of the electric motor for different uses. The power and speed of the electric motor must be suitable for the intended use.

The classification of the electric motor based on the power consumption is generally divided into three categories:

- Small motor (0.05 to 1 hp)

- Medium engine (1 to 400 hp)

- Large electric motor (400 to 50,000 horsepower).

The speed of the alternator should be proportional to the amount of load applied to it. Rated speed is the speed at which the motor operates when fully loaded and supplied with rated voltage.

Most of the speeds in the electric motor for a frequency of 50 Hz are:

- 3000 rpm (two poles)

- 1500 rpm (four poles)

- 1000 rpm (six poles)

When the speed of the motor and the required speed of the equipment connected to it are the same, they are directly coupled. But in situations where the required speed is not equal, equipment such as gearbox, chain or belt between the engine and the desired equipment is used to adjust the speed.

| Speed (rpm) | the power | ||||

| 750 | 1000 | 1500 | 3000 | ||

| Torque(Nm) | kilowatt (KW) | horse power (HP) | |||

| 9.55 | 7.16 | 4.77 | 2.39 | 0.75 | 1 |

| 14 | 10.5 | 7 | 3.5 | 1.1 | 1.5 |

| 19.1 | 14.3 | 9.55 | 4.77 | 1.5 | 2 |

| 28 | 21 | 14 | 7 | 2.2 | 3 |

| 47.1 | 35.3 | 23.6 | 11.8 | 3.7 | 5 |

| 71.3 | 53.5 | 35.6 | 17.8 | 5.6 | 7.5 |

| 95.5 | 71.6 | 47.7 | 23.9 | 7.5 | 10 |

| 140 | 105 | 70 | 35 | 11 | 15 |

| 191 | 143 | 95.5 | 47.7 | 15 | 20 |

| 242 | 181 | 121 | 60.5 | 19 | 25 |

| 280 | 210 | 140 | 70 | 22 | 30 |

| 382 | 286 | 191 | 95.5 | 30 | 40 |

| 471 | 353 | 236 | 118 | 37 | 50 |

| 573 | 430 | 286 | 143 | 45 | 60 |

| 662 | 497 | 331 | 166 | 52 | 70 |

| 764 | 573 | 382 | 191 | 60 | 80 |

| 853 | 640 | 427 | 213 | 67 | 90 |

| 955 | 716 | 477 | 239 | 75 | 100 |

| 1184 | 888 | 592 | 296 | 93 | 125 |

| 1426 | 1069 | 713 | 356 | 112 | 150 |

| 1668 | 1251 | 834 | 417 | 131 | 175 |

| 1897 | 1423 | 949 | 474 | 149 | 200 |

| 2139 | 1604 | 1069 | 535 | 168 | 225 |

| 2381 | 1786 | 1190 | 595 | 187 | 250 |

| 2610 | 1958 | 1305 | 653 | 205 | 275 |

| 2852 | 2139 | 1426 | 713 | 224 | 300 |

| 3323 | 2492 | 1662 | 831 | 261 | 350 |

| 3794 | 2846 | 1897 | 949 | 298 | 400 |

| 4278 | 3208 | 2139 | 1069 | 336 | 450 |

| 5220 | 3915 | 2610 | 1305 | 410 | 550 |

| 5704 | 4278 | 2852 | 1426 | 448 | 600 |

Purchase based on the voltage and frequency of the electric motor

The location where the electric motor is used determines the required voltage and frequency. The supply voltage can be single or three phase. Usually, in Iran, three-phase motors are made in dual voltage 230/460 volts, with a frequency of 50 Hz. Of course, the frequency can be changed using devices such as an inverter to reach the desired shaft speed. The following table is presented in relation to frequency and speed.

| The number of poles | Frequency (HZ) | |||

| 2 | 4 | 6 | 8 | |

| Speed (rpm) | ||||

| 150 | 200 | 300 | 600 | 10 |

| 300 | 400 | 600 | 1200 | 20 |

| 450 | 600 | 900 | 1800 | 30 |

| 600 | 800 | 1200 | 2400 | 40 |

| 750 | 1000 | 1500 | 3000 | 50 |

| 900 | 1200 | 1800 | 3600 | 60 |

| 1050 | 1400 | 2100 | 4200 | 70 |

| 1200 | 1600 | 2400 | 4800 | 80 |

| 1350 | 1800 | 2700 | 5400 | 90 |

| 1500 | 2000 | 3000 | 6000 | 100 |

Purchase based on frame size

The power and speed of the electric motor determine the dimensions of the frame. The size of the frame is actually the distance from the center of the output shaft of the electric motor to the bottom of the base. This information is necessary to install the engine. The table below shows the ratio of frame and shaft dimensions to power and speed.

| Speed (rpm) | the power | ||||||||

| 750 | 1000 | 1500 | 3000 | kilowatt (KW) | horse power (HP) | ||||

| shaft | frame | shaft | frame | shaft | frame | shaft | frame | ||

| – | – | – | – | 9 | 56 | – | – | 0.06 | 0.08 |

| – | – | – | – | 9 | 56 | 9 | 56 | 0.09 | 0.12 |

| – | – | – | – | 11 | 63 | 9 | 56 | 0.12 | 0.16 |

| – | – | – | – | 11 | 63 | 11 | 63 | 0.18 | 0.25 |

| – | – | – | – | 14 | 71 | 11 | 63 | 0.25 | 0.34 |

| 24 | 90 | 19 | 80 | 14 | 71 | 14 | 71 | 0.37 | 0.5 |

| – | – | 19 | 80 | 19 | 80 | 14 | 71 | 0.55 | 0.75 |

| 28 | 100 | 24 | 90 | 19 | 80 | 19 | 80 | 0.75 | 1 |

| 28 | 100 | 24 | 90 | 24 | 90 | 19 | 80 | 1.1 | 1.5 |

| 28 | 112 | 28 | 100 | 24 | 90 | 24 | 90 | 1.5 | 2 |

| 38 | 132 | 28 | 112 | 28 | 100 | 24 | 90 | 2.2 | 3 |

| 38 | 132 | 38 | 132 | 28 | 100 | 28 | 100 | 3 | 4 |

| 42 | 160 | 38 | 132 | 28 | 112 | 28 | 112 | 4 | 5.5 |

| 42 | 160 | 38 | 132 | 38 | 132 | 38 | 132 | 5.5 | 7.5 |

| 42 | 160 | 42 | 160 | 38 | 132 | 38 | 132 | 7.5 | 10 |

| 48 | 180 | 42 | 160 | 42 | 160 | 42 | 160 | 11 | 15 |

| 55 | 200 | 48 | 180 | 42 | 160 | 42 | 160 | 15 | 20 |

| 60 | 225 | 55 | 200 | 48 | 180 | 42 | 160 | 18.5 | 25 |

| 60 | 225 | 55 | 200 | 48 | 180 | 48 | 180 | 22 | 30 |

| 65 | 250 | 60 | 225 | 55 | 200 | 55 | 200 | 30 | 40 |

| 75 | 280 | 65 | 250 | 60 | 225 | 55 | 200 | 37 | 50 |

| 75 | 280 | 75 | 280 | 60 | 225 | 60 | 225 | 45 | 60 |

| 80 | 315 | 75 | 280 | 65 | 250 | 65 | 250 | 55 | 75 |

| 80 | 315 | 80 | 315 | 75 | 280 | 75 | 280 | 75 | 100 |

| 80 | 315 | 80 | 315 | 75 | 280 | 75 | 280 | 90 | 125 |

| 80 | 315 | 80 | 315 | 80 | 280 | 80 | 315 | 110 | 150 |

| 95 | 355 | 80 | 315 | 80 | 280 | 80 | 315 | 132 | 180 |

| 95 | 355 | 95 | 355 | 80 | 315 | 80 | 315 | 160 | 220 |

| 95 | 355 | 95 | 355 | 80 | 315 | 80 | 315 | 185 | 255 |

| 95 | 355 | 95 | 355 | 80 | 315 | 80 | 315 | 185 | 255 |

| 95 | 355 | 95 | 355 | 80 | 315 | 80 | 315 | 200 | 275 |

| – | – | 95 | 355 | 95 | 355 | 90 | 355 | 250 | 350 |

| – | – | – | – | 95 | 355 | 95 | 355 | 315 | 435 |

Purchase based on the type of electric motor housing

The engine housing or frame not only holds the components together, but also protects the internal components from moisture and contamination. The degree of protection and cooling of the engine depends on the type of housing. Electromotor enclosures have two general categories, which are:

- open engine

- closed engine

A good electric motor housing protects the motor from dust, oil, water and high pressure fluids so that the motor can be used in domestic, industrial and harsh environmental conditions. In the following, we will categorize the type of electric motor enclosure based on the NEMA standard and explain each of these terms.

| Type of electric motor working environment | Description |

| ODP | Suitable for clean, dry and well-ventilated closed environments |

| TEFC | Ability to work in dirty, dusty and wet environments. These types of engines have an external fan for moving air and cooling the engine. |

| TENV | It has the same conditions as TEFC, with the difference that in this model of motors, fans are not used and only the passing air flow causes the cooling of the motor. |

| TEAO | It is suitable for environments that have both fans and air blowers. |

Open chamber motors are known as Safe or normal motors. A conventional motor allows air from outside the motor to circulate freely around the coil, while preventing liquid droplets or foreign particles from entering the motor. This parameter is hacked with the abbreviation IP on the electric motor nameplate, the degree of protection of this parameter is explained in the table below.

| The second number | Prime number | degree of protection | Type of electric motor housing | |

| Protection against water | Protection against dust | Protection against accidental contact | ||

| without protection | without protection | without protection | IP00 | Open compartment |

| Protection against water drops even at a vertical angle of 15 degrees | without protection | without protection | IP02 | |

| Protection against vertical drops of water | Non-entry of solid objects with a diameter of more than 50 mm | Protection against accidental contact with hands | IP11 | |

| Protection against water drops even at a vertical angle of 15 degrees | Non-entry of solid objects with a diameter of more than 50 mm | Protection against accidental contact with hands | IP12 | |

| Protection against water drops even at a vertical angle of 60 degrees | Non-entry of solid objects with a diameter of more than 50 mm | Protection against accidental contact with hands | IP13 | |

| Protection against vertical drops of water | Non-entry of solid objects with a diameter of more than 12 mm | Protection against accidental finger contact | IP21 | |

| Protection against water drops even at a vertical angle of 15 degrees | Non-entry of solid objects with a diameter of more than 12 mm | Protection against accidental finger contact | IP22 | |

| Protection against water drops even at a vertical angle of 60 degrees | Non-entry of solid objects with a diameter of more than 12 mm | Protection against accidental finger contact | IP23 | |

| Protection against splashing water from any direction | No entry of solid objects with a diameter of more than 1 mm | Protection against contact with tools | IP44 | Closed compartment |

| Protection against splashing water from any direction | No ingress of harmful dust | Protection against any contact | IP54 | |

| Water ingress protection even at high speed | No ingress of harmful dust | Protection against any contact | IP55 | |

Purchase based on insulation class

Heat is the biggest enemy of the engine. The life of the motor largely depends on the amount of temperature rise of the windings. The main purpose of insulation is to protect the stator windings from heat. The longer the electric motor works at the maximum temperature for the insulation class, its useful life will decrease. For example, the electric motor with insulation class F has lost half of its useful life after 20,000 hours of operation at a temperature of 155 degrees. which is followed by the diagram related to different insulation classes, its relationship with temperature and useful life of the dynamo is placed.

| Insulation class name | insulating material | Maximum coil temperature |

| A | Linen, silk and paper with suitable coating or impregnation with anti-static material such as oil | 105 degrees Celsius |

| B | Fireproof, glass wool, fireproof cotton | 130 degrees Celsius |

| F | Refractory glass (mica), glass wool, fireproof cotton | 155 degrees Celsius |

| H | Silicone rubber, refractory (mica), glass wool, refractory cotton impregnated with materials such as silicone resin. | 180 degrees Celsius |

Buy based on efficiency

The efficiency of the engine indicates what percentage of the input power is transferred to useful work and mechanical power (on the shaft) and how much it wastes as heat. The IEC 60034-30-1:2014 standard has defined four categories for making electric motors in terms of efficiency. These categories are defined by the characteristic codes of IE, which stands for International Efficiency, as follows:

| symbol | Definition |

| IE1 | Standard efficiency |

| IE2 | High efficiency |

| IE3 | Premium efficiency |

| IE4 | Super premium efficiency |

Purchase based on work cycle

Choosing a suitable electric motor also depends on the pattern of power taken from it, which can be constant or variable in a certain period of time, repeating a cycle of changes or load applied to the motor with pulsating or impact torque. Duty cycle is a pattern of power taken over a certain period of time and is expressed as a ratio of time to duty cycle. Frequent starting reduces life because the inrush current during starting quickly heats up the conductors. Duty cycle is also a factor in the size of electric motors.

| level | Level name | Description |

| S1 | Continuous cycle | A constant load is applied to the motor for a specified period of time to achieve time equilibrium. |

| S2 | Short work cycle | A constant load is applied to the engine for a certain period of time, but not enough to reach thermal equilibrium, the rest periods for the engine are enough for the engine to reach the ambient temperature. |

| S3 | Intermittent duty cycle | The work and rest periods are the same and consecutive with a constant amount of load. The motor never reaches thermal equilibrium. The starting current has little effect on the temperature rise. |

| S4 | Intermittent duty cycle with start-up | The start of work, the duration of work and the duration of rest are the same for a given applied load, the engine never reaches the equilibrium temperature, however, the starting current of the engine has an effect on the increase in temperature. |

| S5 | Alternating duty cycle with electric brake | Intermittent and identical start-up period, constant applied load or no applied load to the motor, without rest periods for the motor |

| S6 | Continuous operation with intermittent load | Intermittent and identical work period with a certain load or no load applied to the engine, without rest periods |

| S7 | Continuous operation with electric brake | Identical and alternating start-up periods, continuing with a constant amount of applied load with electric braking, without rest periods. |

| S8 | Continuous operation with periodic changes in load and speed | Intermittent and identical work periods with a certain applied load and speed, as well as continuing to work with variable speed and applied load, without having a rest period. |

Purchase based on installation environmental conditions

Usually , a series of conditions should be considered regarding the installation environment of the electric motor in order to maximize the life of different parts of the 3-phase motor, such as insulation between coils, bearings, grease used in bearings , etc. The most important of these conditions is related to temperature, humidity, vibration, height, etc. at the installation site. Usually, the rated power and current of the electric motor is designed for a maximum temperature of 40 °C and an altitude (above sea level) of 1000 meters. If the ambient temperature and altitude conditions exceed these values, the electric motor must be under load less than the rated value. Values and coefficients should be applied according to the manufacturer’s instructions.

Synchronous electric motor

A synchronous motor is an AC motor in steady state whose shaft rotation is equal to the frequency of the input current. Synchronous motor is a type of AC motor and the total number of revolutions performed by the shaft of this type of electric motor is equal to the integer number of the applied current frequency. Synchronous motors do not rely on induced current to operate. In these motors, unlike the induction motor, there are multi-phase electromagnets on the stator that produce a rotating magnetic field. Here the rotor is a permanent magnet that synchronizes with the rotating magnetic field and rotates at the same frequency as the current applied to it.

Synchronous electric motor performance

The way synchronous motors work depends on the interaction between the magnetic field of the stator and the magnetic field of the rotor. The stator contains a number of coils that have 3-phase electricity. Therefore, the stator coils produce a rotating magnetic field based on 3-phase electricity. DC power supply is given to the rotor. The rotor enters the rotating magnetic field produced by the stator windings and rotates simultaneously. The rotation speed of the synchronous motor depends on the frequency of the input current to the electric motor. The speed of the synchronous motor is controlled by the frequency of the applied current. The speed of a synchronous motor can be calculated as follows.

S=60f/P=120f/p

f = frequency of AC current (Hz) / p = total number of poles in each phase / P = total number of pairs of poles in each phase

If the power taken from the motor is more than the maximum power produced by the synchronous electric motor, the motor will go out of synchronous mode. The 3-phase winding of the stator makes it possible to determine the direction of rotation of the electric motor. Whereas in single phase winding, the direction of rotation cannot be obtained and the motor can start rotating in any direction. To control the direction of rotation in these synchronous motors, initial settings are required.

Application of synchronous electric motor

Synchronous motors are used to create a certain and constant speed and can be used in applications where constant speed rotation is required. These motors are not self-starting, and if you need a self-starting motor, you should not choose synchronous motors. The efficiency in these motors is higher and more than 90% compared to most AC and DC motors. Synchronous motors are suitable for conditions that require low speed and high power motors and are the best power generation option for stone crushers and all types of mills. The speed of these motors remains constant regardless of the load and their speed can only be changed through the VFD because the input current is directly related to the output speed. The efficiency of these motors helps correct the inefficiencies of induction motors and provides a means of correcting distribution losses.

Electric motors are one of the most widely used equipment in various industries. These industrial equipments convert electrical energy into mechanical energy and can be connected to the circuit in single phase or three phase according to the input current. In this article, an attempt is made to provide more details about three-phase electric motors or induction motors.

Electric motor online shopping

Buying an electric motor requires a lot of time and research, especially if you are looking for an electric motor with a good price or special performance. A quality electric motor can be obtained from reputable sales centers. The most important thing about buying an electric motor is its technical specifications like the following:

- Electric motor power

- voltage and frequency

- Frame size

- Type of electric motor housing

- Insulation class

- work cycle

What is an electric motor?

An electric motor (or electromotor ) is an electric machine that converts electrical energy into mechanical energy. Most electric motors work through the interaction between the motor’s magnetic field and the electric current in the winding. This force interaction (according to Faraday’s law) creates a torque force that is applied to the motor shaft. An electric motor can be powered by direct current (DC) sources such as batteries or rectifiers or by alternating current (AC) sources such as inverters, electric generators or the power grid. The electric motor is the reason for the emergence of many technologies that we enjoy in the 21st century. Without motors, we would still be living in the days of Thomas Edison, when the only purpose of electricity was to turn on light bulbs. Electric motorThey are found in cars, trains, electrical equipment, fans, air conditioners, home appliances, disk drives, and more. Some electric clocks even use small dynamos. There are different types of motors that are made for different purposes.

The basic principle of operation of an electric motor is Faraday’s law of induction. That is, when an alternating current interacts with a changing magnetic field, force is created. Since the invention of the electric motor, there have been many advances in this field of engineering and it has become a very important topic for today’s engineers. Below are all the main electric motors in use today.

Types of electric motors

The different types of electric motors are:

- DC motors

- Synchronous motors

- Three-phase induction motors (asynchronous motor)

- Single-phase induction motors (asynchronous motor)

- Other special and ultra-special motors (such as stepping motor)

In the diagram below, electric motors are classified:

Among the four main classifications of motors mentioned above, the DC motor, as the name suggests, is the only motor that is powered by current. This is the most basic version of an electric motor in which a rotating torque is produced due to the passage of current through a conductor in a magnetic field. The rest of the electric motors are of the AC type and are driven by alternating current, for example, the synchronous motor, which always runs at synchronous speed. Here the rotor is an electromagnet that is magnetically locked to and rotates with the rotating magnetic field of the stator. The speed of these machines is determined by changing the frequency (f) and the number of poles (P) using the following formula.

There is another type of AC motor in which the rotating magnetic field cuts the rotor conductors, thus creating an eddy current in the short-circuited rotor conductors.

Due to the interaction of the magnetic field and these circulating currents, the rotor starts to rotate and continues to rotate. It is an induction motor, also known as an asynchronous motor, which operates at a speed lower than its synchronous speed, and the rotational torque and speed are controlled by a slip change, which is the difference between the synchronous speed Ns and the rotor speed Nr it shows.

Due to changing flux density, it governs the principle of EMF induction. Therefore, this electric motor is called an induction machine. A single-phase induction motor, like a three-phase motor, works on the principle of emf induction due to the presence of flux. But unlike the three-phase electric motor, the single-phase electric motor works with a single-phase power supply. Single phase motor starting methods are based on two well-established theories, i.e. rotating field theory and orthogonal field theory.

Three-phase electric motor

Single phase electric motor

Apart from the four main types of electric motors mentioned above, there are several special types of electric motors . These include:

- Linear Induction Motors (LIM)

- Waste engine

- stepper motor

- Servo motor

Each of these engines has special features that have been developed according to the needs of the industry or for use in a specific equipment. For example, the reciprocating motor is used in wristwatches due to its small and compact nature. A hysteresis motor is defined as a synchronous motor that has a cylindrical rotor and operates on hysteresis losses caused by a hard steel rotor with high maintainability. This motor is single phase and its rotor is made of ferromagnetic material with non-magnetic support on the shaft. A reciprocating engine is made up of five main components:

- Stator

- Single phase stator winding

- rotor

- shaft

- Shadow coil

- Frequently Asked Questions

-

The electric motor can be considered the main part of the industry. Electric motors are tools for converting electrical energy into mechanical energy, which are available in Iran in three types: three-phase, single-phase and DC. Contact the sales experts to choose three-phase and single-phase electric motors.

There are many brands of electric motors in Iran. One of the best of these brands is Siemens Electromotor, but similar brands such as WEG, VEM, and Vemat Italy also have many fans. Among the Iranian brands, Motogen Tabriz, Electrogen and Dieselsaz can be mentioned. In the industrial goods website, we try to list the prices of all products and suggest the best option.

In powers up to 3.6 kilowatts, this work can generally be done with measures and the use of capacitors. But this is not possible for electric motors with higher power. In addition to using a capacitor, you can use a single-phase to three-phase inverter, which is also possible for low powers.

Electric motor, agriculture, what characteristics are

Nowadays, there is no electric motors do a lot of things difficult. Agriculture, too, of this rule,…

DC electric motor

What is a DC electric motor? Direct current (DC) electric motor is a type of electric motor…

what is vem electronics

I found a few results for “VEM electronics”. However, I am not sure which one you…

Electric motor Helmke

Made by HELMKE 100 years of experience, etc. used in all over the world and maximum…

Siemens Electric Motor

Shop be the industry representative, the official import of motor Siemens, siemens , the German models The…

The cause of the hot electric motor mean? + Ways to reduce the temperature, alternator, industrial

The cause of the hot electric motor mean? + Ways to reduce the temperature, alternator, industrial…

ATB Electromotor

Electric motor ATB SEVER Electric motor ATB SEVER in between products and brands, European, electric motors available…