What is a pin mill?

Industrial pin mill (Pin mill), which is sometimes known as universal mill, is one of the types of impact mills that use pins on a fixed disk and a moving disk to process powder and micronize materials. It does mineral, food, chemical, pharmaceutical, etc.

MFA provides all kinds of pin mill machines with different sizes and capacities and also equipped with cyclone or bag filter.

Mineral mill price list

Technical specifications of pin mill mill

The capacity of the micronized pin mill depends on various factors, including its dimensions, and varies between 100 and 10,000 kg per hour. The parts of this industrial grinding machine are made of steel, iron or cast iron, which increases its strength and resistance. The dimensions of the grains output from this mill are usually around 100 to 300 microns.

Types of pin mills

Peel mill is considered as a series of industrial machines and has different designs. In the following, we will introduce these models in full.

Cyclone pin mill

In some pin mills that produce soft powder, an air separator such as a bag filter or cyclone is used, which absorbs the powdered material and removes it uniformly from the machine. A pin mill with a cyclone or bag filter greatly improves product quality and reduces the impact of chemical and environmental factors on the product.

Lattice pin mill

In pin mill mills, nets are usually used so that materials that are not well ground are trapped by nets with large holes and enter the mill chamber again.

pin mill without mesh

Some pin mills are designed and made without mesh. In this model of pin mill mills, many pins are used which are compact and intermingled and hit the material at high speed. As a result, the materials are more powdered and come out of the machine almost uniformly and do not need a net on the way out. The pin mill without mesh has the ability to grind wet and sticky materials without clogging or disrupting the operation of the device.

Pin mill components

- Hopper: The materials are stored in the hopper or the holding chamber, which is conical in shape, to enter the mill when the inlet valve is opened.

- Screw Feeder: Materials are usually directed to the mill tank with the help of a metal screw or spiral.

- Magnet: Sometimes a magnet is placed in the material inlet to prevent iron parts and scraps from entering the chamber.

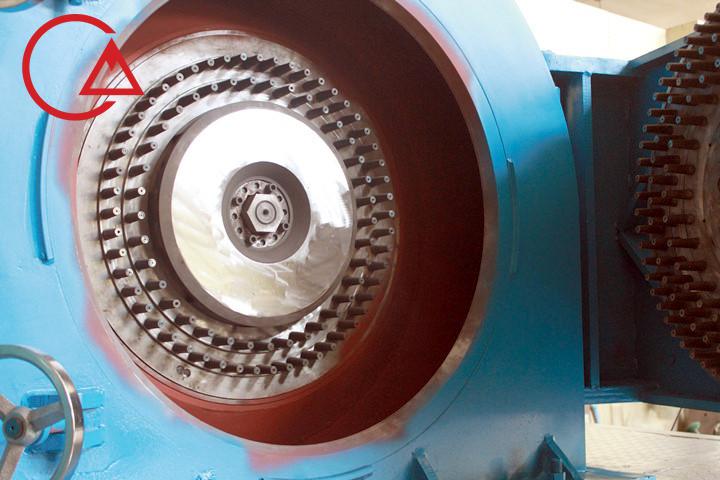

- Discs: The pin mill has two discs, one of which is usually fixed and installed on the mill door, and the other is movable and installed on a rotor that rotates with power.

- Pins: Pins are steel parts that are mounted on discs and rotate with the disc and grind the material.

- Rotor: The rotor is responsible for rotating the disk with the help of the shaft in the pin mill.

- Air Separator: In order to micronize the materials and turn them into very soft powders, the pin mill needs an air separator such as a cyclone or bag filter to absorb the powders and remove them from the machine.

- Electric gearbox: The power produced by the electric motor is usually transferred to the rotor by the gearbox.

- Mesh or sieve: If it is necessary to sieve the output material in some pin mill mills, a sieve or mesh is used so that the output product is poured on it and the larger sizes are separated and returned to the grinding chamber of the machine for re-grinding.

How pin mill works

The way the universal grinding machine works is that the materials inside the hopper are poured into the grinding chamber through a screw feeder. This chamber is surrounded by two disks, one of which is fixed and the other one rotates at a low or high speed according to the amount of impact required, and the pins on the disks pass by each other and the material becomes powder. The powdered materials, which are located in the outermost part of the disk due to the centrifugal force caused by the rotation of the rotor, fall from the edges of the disks and are discharged from the lower valve, or they are entered into a cyclone or filter bag by the suction of the fan. Cyclone shaft pin is absorbed by centrifugal force and filter bag pin shaft is absorbed with the help of filter bags and is uniformly removed from the device.

Pin mill application

The pin mill machine is widely used in the field of mining, and for this reason, it was initially known as a mineral mill. One of the main uses of this device is to grind the following materials:

- All kinds of minerals

- Chemical

- dietary

- cosmetic

- Medicinal

- Production of spices

- flour

- starch

- Sugar

- fertilizer,

- Pigments

- Labs

Advantages of pin mill mill

- high efficiency

- Low energy consumption

- Quality product

- High strength

- Automatic operation

- Ability to produce very soft powders

pin mill price

Sorry, all prices are being updated, please contact the sales department to inquire about the purchase price.

| Row | Description | Price in Tomans |

| 1 | pin mill price | Call |