سری گاما ایکس ال پرومیننت که در ماه گذشته در نمایشگاه آخما آلمان معرفی شد، ترکیبی از مزایایی دوزینگ پمپ سری دلتا و سری گاما ایکس است.

The New Gamma XL is a mixture of Delta Pump strength and GammaX Intelligence

The Gamma XL

extends the performance spectrum of ProMinent’s intelligent solenoid metering pump series gamma/ X. The Gamma XL is as smart, easy to use and has the same long service life as its smaller sister model. With a higher capacity range of 8 to 80 l/h at 25 to 2 bar, the gamma/ XL increases the versatility of the gamma/ X product range and opens numerous new fields of application

The new gamma/ XL

is “Ready for Industry 4.0”. Designed as a smart product, it can be connected to ProMinent’s web-based fluid management platform Dulconnect. For the digital fluid management, the solenoid-driven metering pump includes integrated Profibus and CANopen interfaces for the connection to process control systems. Thus, the gamma/ XL allows you to monitor, analyse and optimise metering processes with ease. In this way, metering processes can be monitored in real time, avoid downtimes avoided and reports generated fully automatically. An additional highlight of the new gamma/ XL is its extended connectivity

This minimizes the consumption of raw materials used, operating errors, and down times. At the same time, the customer service is improved through networking, transparency, and automation, and the timely delivery, maintenance, and repairs on site are ensured

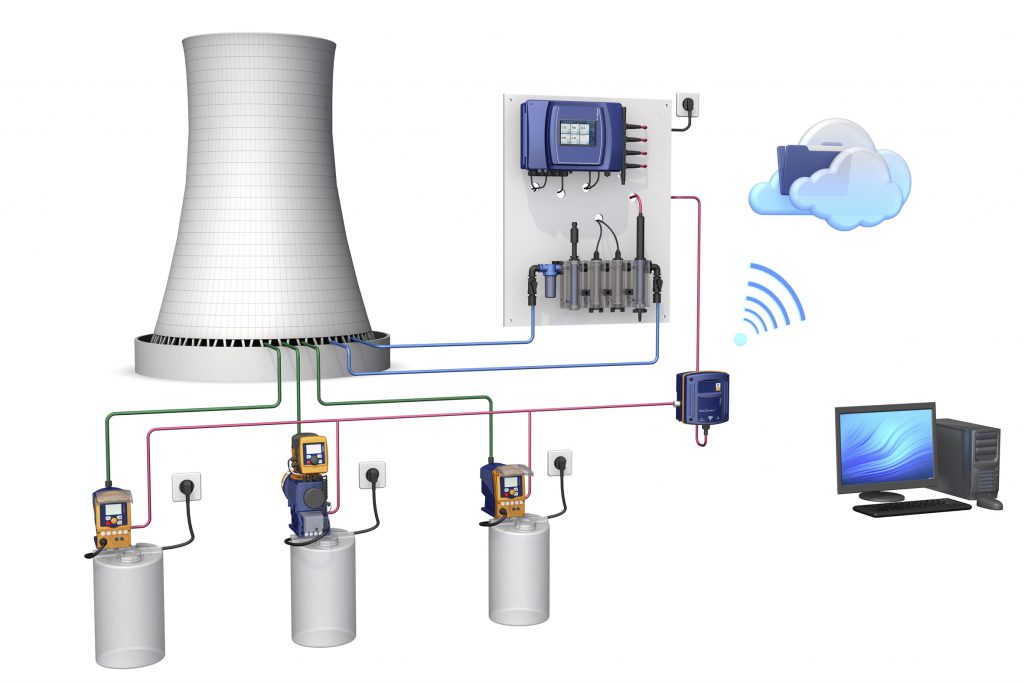

سیستم آنلاین کنترل کولینگ تاور

ProMinent at Pumps & Valves 2019

Solutions for digital fluid management

ProMinent is emphasising its expertise in forward-looking metering technology at the trade fair for industrial pumps, fittings and processes, Pumps & Valves in Dortmund, Germany, on 20 and 21 February 2019. The company is presenting smart solutions for digital fluid management on Stand R 51-6 in Hall 6 in the Westfalenhalle. Highlights of the Heidelberg-based manufacturer’s stand will be motor-driven and solenoid metering pumps as well as peristaltic pumps. As smart products, these are linked to the web-based fluid management platform via a DULCOnneX gateway.

For digital fluid management,

the solenoid-driven metering pump gamma/ XL, the motor-driven metering pump Sigma X and the peristaltic pump DFBa with Sigma control are suitably equipped for linking to process control systems with an integrated Profibus and CANopen interfaces. This allows the operator to monitor, analyse and optimise metering processes with ease. Operating mistakes and downtimes are avoided. The consumption of the raw materials used is minimised. At the same time, the customer service can be improved through networking, transparency, and automation, and the timely delivery, maintenance, and repairs on site can be ensured.

The design of the other highlight, the high-pressure process metering pump Orlita® Evolution, ensures maximum process reliability and flexibility: a sectional model will allow visitors to see inside the pump.